Paul351W

Member

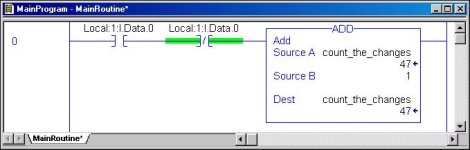

I'm running a CLX setup with the high speed analog I/O cards. I have a rung where I am doing a calculation, and check the divisor variable to make sure it is above zero.

I was getting some weird results every once in a while for a couple scans and determined that the CPT statement was executing when the dividing variable was below zero, despite my GRT 0 statement at the beginning of the rung.

I knew that the CLX I/O updates independently of the program scan, but I never thought that the I/O values could change between instructions on the same rung. Is buffering the I/O the only way to get rid of this problem?

I was getting some weird results every once in a while for a couple scans and determined that the CPT statement was executing when the dividing variable was below zero, despite my GRT 0 statement at the beginning of the rung.

I knew that the CLX I/O updates independently of the program scan, but I never thought that the I/O values could change between instructions on the same rung. Is buffering the I/O the only way to get rid of this problem?