TimD

Lifetime Supporting Member

Hello,

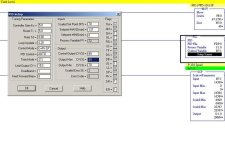

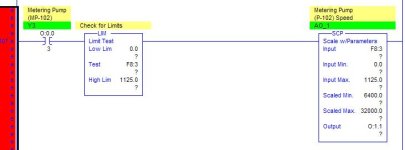

Attached is my PID setup. I am trying to vary the speed of a pump to keep water in a tank at 70 inches.

Everything works, as long as my %output is not 90% when the output is commanded. When not commanded, I can freely set the high limit to 100% and watch the output integer go to max. As soon as the command to run at the CV%, and over 90%, I get a fault and the controller freezes (minor overflow bit S5).

I have an SCP block controlling a VFD.

Please see picture Attached.

Anyone know why I get a fault over 90%, please help me! I think it is like a div/0 issue here?

Thank You!

Attached is my PID setup. I am trying to vary the speed of a pump to keep water in a tank at 70 inches.

Everything works, as long as my %output is not 90% when the output is commanded. When not commanded, I can freely set the high limit to 100% and watch the output integer go to max. As soon as the command to run at the CV%, and over 90%, I get a fault and the controller freezes (minor overflow bit S5).

I have an SCP block controlling a VFD.

Please see picture Attached.

Anyone know why I get a fault over 90%, please help me! I think it is like a div/0 issue here?

Thank You!