mrtweaver

Member

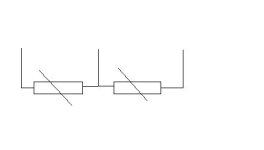

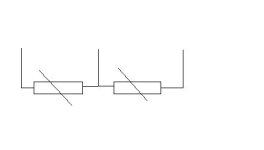

We have this piece of equipment that has on what appears to be two sensors. I have included a drawing of the schematic symbol used, although I am unfamiliar with the symbol. Thought maybe someone could tell me more about the symbol.

The details of the sensor are: Metal Housing, extended sensing tip, 1/2inch diameter metal housing, 1 1/2 inch long metal housing, 3/8inch diameter extended tip, 1/8inch long extended tip, extended tip is made of plastic, what appears to be where the actual sensing materials are is a 3/16 square discoloration in the center of the extended tip, it is a 3 wire sensing device, and it is made in Germany. A photo of it along side a ruler will be following.

I have had no luck locating this sensing device other than going back to the OEM and they do not want to give any pertinent info on the device. You see the device reads a timing pully, reads the teeth on it. There is a black dot on the sensor, according to what limited information I can obtain the black dot needs to be lined up on the same plane as the teeth on the timing pully, however if this is done, when you place a scope on the sensor, the signals do not match what is required by the system. If I rotate the sensor sometimes it gets better. What I would really like to do is find a data sheet on the device so I know how the manufacturer orients the sensing tip, what the manufacture recomends as a sensing distance, and other such pertinent info. The manufactuer of the machine is BOWE. It is a guilotiene style paper cutter.

So with all that said has anyone here had any experience with BOWE cutters and the sensors? Can they tell me anything about the sensors? Can someone tell me more about the schematic symbol?

Thanks and have a great day.

The details of the sensor are: Metal Housing, extended sensing tip, 1/2inch diameter metal housing, 1 1/2 inch long metal housing, 3/8inch diameter extended tip, 1/8inch long extended tip, extended tip is made of plastic, what appears to be where the actual sensing materials are is a 3/16 square discoloration in the center of the extended tip, it is a 3 wire sensing device, and it is made in Germany. A photo of it along side a ruler will be following.

I have had no luck locating this sensing device other than going back to the OEM and they do not want to give any pertinent info on the device. You see the device reads a timing pully, reads the teeth on it. There is a black dot on the sensor, according to what limited information I can obtain the black dot needs to be lined up on the same plane as the teeth on the timing pully, however if this is done, when you place a scope on the sensor, the signals do not match what is required by the system. If I rotate the sensor sometimes it gets better. What I would really like to do is find a data sheet on the device so I know how the manufacturer orients the sensing tip, what the manufacture recomends as a sensing distance, and other such pertinent info. The manufactuer of the machine is BOWE. It is a guilotiene style paper cutter.

So with all that said has anyone here had any experience with BOWE cutters and the sensors? Can they tell me anything about the sensors? Can someone tell me more about the schematic symbol?

Thanks and have a great day.