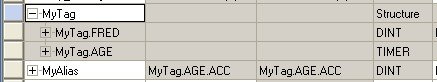

Yea, aliases are fine and dandy, if the previous person did it in a neat manner. I don't see the need to alias inputs and outputs when you can type a clear text description in for that IO point and it follows it everywhere in the code.

Aliases used for I/O have a number of benefits, including...

1> You can write your code, test and debug it,

before the control panel set-up is finalised. I have had instances where the locationOn of I/O is changed during plant design. I have even had panels added/deleted at design time. I/O points created as Internal tags can easily be changed to alias tags at a later stage, without involving any editing of the code.

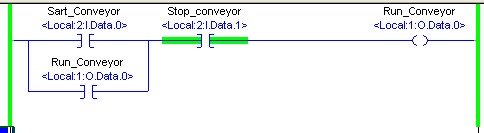

2> You don't need descriptions at all if the alias tag-name conveys sufficient meaning. Handy for the occasional time when you need to, or have to, go online without the .ACD file, the upload will show your I/O points clearly. It's better than nothing at all.

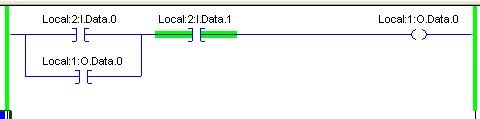

3> The ladder display shows the alias information (if the option is turned on), in such a way that it is immediately obvious which of your code is referencing I/O data, and which are internal tags.

4> Once defined, I do not care

where my I/O physically

is, but I do care

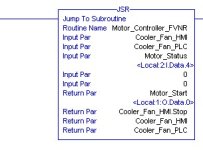

what my I/O

does, so I prefer to reference it as a tag-names, rather than arbitrary addresses, leaving me the freedom to attach descriptive text or not, most times there is no need.

5> Wiring changes are easily handled, just by editing the tag alias information, there is no need to do Search/Replace operations through the logic, which is time-consuming on large projects.

IMHO there are no benefits in

not using them, and I make it a rule to

never reference I/O directly in any code I write.