Hi

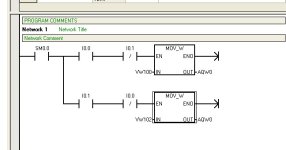

I wish to write a programme that outputs one of several preset analogue outputs selected by input switches.

Im not sure how to configure the preset analogue values.

I think I need to create a DataBlock

assign data to memory locations but not sure what syntax.

eg M0.0 = 256

then use MOV M0.0 to AQ1 BIT such and such

can anyone help?

thanks

MG

I wish to write a programme that outputs one of several preset analogue outputs selected by input switches.

Im not sure how to configure the preset analogue values.

I think I need to create a DataBlock

assign data to memory locations but not sure what syntax.

eg M0.0 = 256

then use MOV M0.0 to AQ1 BIT such and such

can anyone help?

thanks

MG