sounds like you've already got a pretty good headstart ... I'm not sure where you're having your problem ... let us know if the following is not what you're looking for ...

here's how I would go about testing the modules you've listed so far ...

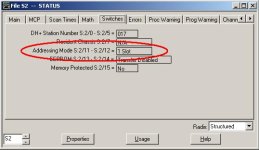

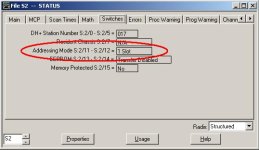

(1) make sure that the chassis DIP switches are set as shown in red in the picture attached ... other settings are possible – but this will be the simplest ...

(2) put the processor into the chassis (in the far left slot) and download a brand new "starter" program with NO control rungs ... go online with the processor ... make sure that the processor is in the RUN mode ...

(3) check the Processor Status file and confirm that the addressing mode is set for 1 Slot (as shown in figure below) ...

(4) monitor the Input Data File/Table ...

(5) install a 1771-IBN input module in the next slot (just after the processor) ...

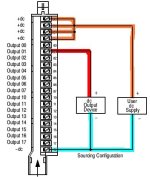

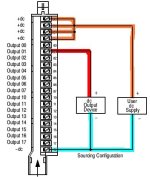

(6) wire up the input module using a 24VDC power supply ... connect the OVDC (return path) to all of the terminals marked in blue ...

(7) as you connect a wire carrying +24VDC (from the DC power supply) to each of the "input" terminals (the ones that do NOT have 0VDC connected to them) the input bits (shown in red) should change from a ZERO status to a ONE status on the Input Data File/Table ... the appropriate LED should also light up on the front of the input module ... note that the module you listed has 32 inputs – so TWO words (two 16-bit "rows") will be involved on the Input Data File/Table ...

survival tip: some "swing arm" terminal strips must have the screws snugged down in order to make electrical contact with the "business end" of the module ... if you leave the screws loose and test by just touching/probing the screw, you might not make electrical contact with the module's circuitry ... specifically, it might look like the input is "bad/open" even though it's perfectly OK ... so ... snug the screws before you probe them ...

(8) put a 1771-OBD output module in the next slot (next after the input module) ...

(9) wire up the output module using a 24VDC power supply ... connect the +24VDC to all four screws at the top of the module as shown ... connect the 0VDC (return path) to the bottom screw as shown ...

survival tip: instead of using a voltmeter for testing, use something like a relay with a 24VDC coil ... reason: most transistor/solid-state type output modules have a certain amount of "leakage" current which continues to flow through the output circuit – EVEN WHEN THE OUTPUT IS TURNED OFF ... this current is often high enough to fool a sensitive meter ... specifically, the output might test "ON" – even though it's actually "OFF" ... but ... using a suitable relay coil will "load" the circuit enough to eliminate the false "ON" reading ... also remember to "snug" the screws before testing/probing them ...

(10) connect one side of the relay coil to the 0VDC (return path) as shown highlighted in blue ... now probe each of the "output screws" with a wire connected to the other side of the relay coil – (highlighted in red) ... the relay should energize (ON) when you type a ONE into the appropriate bit/box on the Output Data File/Table (highlighted in yellow) ... the relay should de-energize (OFF) when you type a ZERO into the appropriate bit/box ... note that you do NOT need to program in any control rungs to "turn on" the outputs ... just manually typing ONEs and ZEROs into the bit/boxes will be sufficient for a test ... you also do not need to "Force" the outputs on and off ...

(11) as you test each output, also confirm that the appropriate LED lights up on the front of the output module ...

see if this is enough to get you going ... I apologize in advance for the inevitable typographical errors ... it's late – and I'm tired ... there are plenty of other forum members who can straighten out any mistakes I've made ... hopefully this will make a good "first draft" ...

another quick question for you: do you understand Block Transfer Read and Block Transfer Write operations? ... you'll need them for testing the analog modules ...

good luck with your project ...