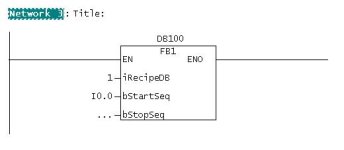

I will prepare a program with S7-300.There are nearly 30 conveyor bant motors.Numbers are 1.2.3.etc...30.These motors will not run always.I will write recipes on WinCC.For example ;

Recipe1:motor4,5,7,1,8,9.

Recipe2:motor3,6,5,1,2,4,20,24,9,30.

Recipe3:motor1,2,4,7.

.

.

.

If I selected one of them and give start the system,motors will operated step by step (with timer operation)according the queue.Is there any simple solution of like this system?Has any experience?Thanks in advance.

Recipe1:motor4,5,7,1,8,9.

Recipe2:motor3,6,5,1,2,4,20,24,9,30.

Recipe3:motor1,2,4,7.

.

.

.

If I selected one of them and give start the system,motors will operated step by step (with timer operation)according the queue.Is there any simple solution of like this system?Has any experience?Thanks in advance.