69FIREBIRD

Member

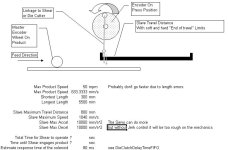

Hi All, I have been asked to look at a flying shear tube mill and improve on its accuracy currently running at up to +/- 3mm and needs to get down to a consistent +/- 1mm. Current hardware is a 1756-L60M03SE processor/sercos interface, M02AE MO2E & Ultra 3000 DSD-HV150-SE drive.

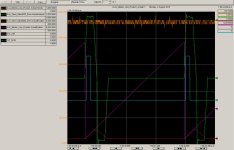

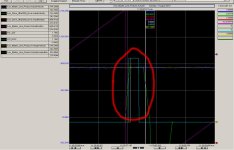

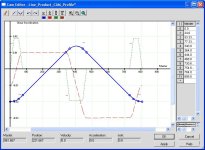

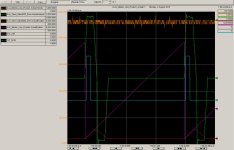

Could I get some feedback on the trend I have compiled. When I review it I see the slave (shear) “actual” velocity overshooting the master “actual” velocity, the master “actual” velocity “flicking” up and down, and the slave “actual” position lagging the master position. Is “actual” the correct thing to be trending to get a true representation of what is happening or should I be looking at “average”

The "CUT_NOW" and the "SOL _235" are the respective cut control logic and pneumatic cut solenoid – which trends a consistent electro/mechanical/pneumatic interval time – so I’m not suspecting that as an issue in respect to the accuracy. To me there looks to be a requirement to tune things up to improve the accuracy.

I note that the the majority of the program is built in the continuous task folder with several low level perodic taks for minor aux control/interfacing and question whether it should be grouped into periodic and event based tasks.

I’ve started wading through some of the manuals – but I’m on the step part of the learning curve at the moment.

I’d be interested in your thoughts and directions options I can take to improve the accuracy of this system.

Thanks.

Could I get some feedback on the trend I have compiled. When I review it I see the slave (shear) “actual” velocity overshooting the master “actual” velocity, the master “actual” velocity “flicking” up and down, and the slave “actual” position lagging the master position. Is “actual” the correct thing to be trending to get a true representation of what is happening or should I be looking at “average”

The "CUT_NOW" and the "SOL _235" are the respective cut control logic and pneumatic cut solenoid – which trends a consistent electro/mechanical/pneumatic interval time – so I’m not suspecting that as an issue in respect to the accuracy. To me there looks to be a requirement to tune things up to improve the accuracy.

I note that the the majority of the program is built in the continuous task folder with several low level perodic taks for minor aux control/interfacing and question whether it should be grouped into periodic and event based tasks.

I’ve started wading through some of the manuals – but I’m on the step part of the learning curve at the moment.

I’d be interested in your thoughts and directions options I can take to improve the accuracy of this system.

Thanks.