alex_cordova

Member

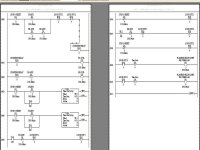

here it is:

i have been on this project for days

i need to write code for 2 motors, 2 flashing fault lights and 4 inputs thats it , no more!!!!! this is for school!! Here is the scope.

Write the PLC logic so that if the system is stopped both motors will stop and if either motor trips an overload a pilot light will flash on and off to indicate which motor has faulted.The lights will continue to flash and disallow the system from being started even after the overload has been reset. Pressing the stop button should reset the system and allow the motors to start back up when the start button is pressed.

I:0/0 stop/reset button

I:0/1 start button

I:0/2 M1 aux coil

I:0/3 M2 aux coil

O:0/0 m1 coil

O:0/1 m2 coil

O:0/2 flashing fault light over load m1 coil

O:0/3 flashing fault light over load m2 coil

this program is easy using other contacts, like the ones on the starter that are normally closed which are 5 and 6 or the ones that come with the solid state over load for allen bradly which are the normally open contacs 97-98.

But my instructor said to write code only using the holding contacts which have terminals numbers marked 2 and 3 on the starters thats it!!!

OK i did , and everything is fine , but i have one problem!

if m1 coil is still triped when i hit the start button, m2 coil wont come on at all and fault light will come on fast saying m1 coil is still faulted which is fine

here is the problem when its the other way around, if m2 is still tripped by overloads, M1 coil will kick it for about 1/4 of a second then drop out becuase m2 coil is in fault condition, i have tried very hard to fix this for days but i cant is this possible.

i have been on this project for days

i need to write code for 2 motors, 2 flashing fault lights and 4 inputs thats it , no more!!!!! this is for school!! Here is the scope.

Write the PLC logic so that if the system is stopped both motors will stop and if either motor trips an overload a pilot light will flash on and off to indicate which motor has faulted.The lights will continue to flash and disallow the system from being started even after the overload has been reset. Pressing the stop button should reset the system and allow the motors to start back up when the start button is pressed.

I:0/0 stop/reset button

I:0/1 start button

I:0/2 M1 aux coil

I:0/3 M2 aux coil

O:0/0 m1 coil

O:0/1 m2 coil

O:0/2 flashing fault light over load m1 coil

O:0/3 flashing fault light over load m2 coil

this program is easy using other contacts, like the ones on the starter that are normally closed which are 5 and 6 or the ones that come with the solid state over load for allen bradly which are the normally open contacs 97-98.

But my instructor said to write code only using the holding contacts which have terminals numbers marked 2 and 3 on the starters thats it!!!

OK i did , and everything is fine , but i have one problem!

if m1 coil is still triped when i hit the start button, m2 coil wont come on at all and fault light will come on fast saying m1 coil is still faulted which is fine

here is the problem when its the other way around, if m2 is still tripped by overloads, M1 coil will kick it for about 1/4 of a second then drop out becuase m2 coil is in fault condition, i have tried very hard to fix this for days but i cant is this possible.

Last edited: