You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

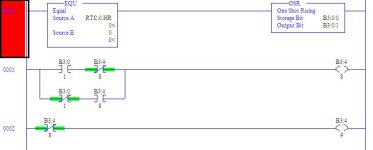

RSLogix 500 24 hour cycle logic

- Thread starter bearsgone

- Start date

bernie_carlton

Lifetime Supporting Member + Moderator

Re: bernie_carlton

Thank you for the sample but I can not seem to make it work on ML1400. it does not switch

Thank you for the sample but I can not seem to make it work on ML1400. it does not switch

Mickey

Lifetime Supporting Member

Thank you for the sample but I can not seem to make it work on ML1400. it does not switch

Post your code (.RSS file)and someone will take a look.

bernie_carlton

Lifetime Supporting Member + Moderator

Make sure that B3:0/0 and B3:0/1 are not used elsewhere in your code. I just picked those two as examples. The other two bits were from your posted code.

RE: bernie_carlton

I am trying to implement 3 pump 24 hour solution. Only two pumps at any given time should be running and they would alternate every 24 hours. Can not seem to get the logic right, should I be using two OSRs?

Thank you

I am trying to implement 3 pump 24 hour solution. Only two pumps at any given time should be running and they would alternate every 24 hours. Can not seem to get the logic right, should I be using two OSRs?

Thank you

OkiePC

Lifetime Supporting Member

Increment a counter every 24 hours using the logic Bernie provided. Set the preset to 3, on the next rung if the counter is DoNe, RESet it.

When the .acc = 0, run pumps 1,2

When the .acc = 1, run pumps 2,3

When the .acc = 2, run pumps 1,3

When the .acc = 0, run pumps 1,2

When the .acc = 1, run pumps 2,3

When the .acc = 2, run pumps 1,3

Hot dog, now we are getting down to it!

Now, if one pump fails and you need to pull it out of the rotation ???

As Alaric has pointed out before, if you run them equal times with equal loads, then they will all fail at about the same time. So now instead of one main pump worn out and needing replacing (while you keep running the other two), you got to shut down and replace all three!

Actually, equal time may not cause them to fail at the exact same time, but in the same fiscal year. The company accountants may not want to wreck the maintenance budget by allocating money for 3 pumps the same year, so....

They don't teach the financial part in PLC school, but just how to run the motors evenly.

In the real world of high company finance:

1st Year, you would buy Pumps 1 and 2 and run evenly, taking a tax break for capital depreciation for 2 pumps.

2nd Year, buy Pump 3 and run Pumps 1 and 3 evenly, taking a tax break for capital depreciation for 3 pumps.

3rd Year, run Pumps 1 and 2 evenly, taking a tax break for capital depreciation for 3 pumps.

4th Year, run all 3 Pumps evenly, taking a tax break for capital depreciation for 3 pumps.

....

Run until Pump 1 fails (most wear), replace it and continue even rotation.

...

Run until Pump 2 fails (next most wear), replace it and continue even rotation

....

Run until Pump 3 fails, replace it, and continue even rotation.

...

Repeat cycle.

Hopefully, the pumps will fail in different years, allowing the accounts time to recover from the shock. But you got Murphy's Law to contend with, so Pump 3 might actually fail first!

In years with sympathic tax laws, you may get Accelerated Depreciation, which makes buying new equipment effectively cost less. So instead of contiuning to run an old pump, it may be cheaper overall to buy a new one, if you can claim enough Depreciation the first year to pay for it. In years of increasing business taxes (like 2011), you may have to skip the replacement altogether. Our screwed-up convoluted tax code is one reason businesses are not expanding.

Now write a program for the above!

Now, if one pump fails and you need to pull it out of the rotation ???

As Alaric has pointed out before, if you run them equal times with equal loads, then they will all fail at about the same time. So now instead of one main pump worn out and needing replacing (while you keep running the other two), you got to shut down and replace all three!

Actually, equal time may not cause them to fail at the exact same time, but in the same fiscal year. The company accountants may not want to wreck the maintenance budget by allocating money for 3 pumps the same year, so....

They don't teach the financial part in PLC school, but just how to run the motors evenly.

In the real world of high company finance:

1st Year, you would buy Pumps 1 and 2 and run evenly, taking a tax break for capital depreciation for 2 pumps.

2nd Year, buy Pump 3 and run Pumps 1 and 3 evenly, taking a tax break for capital depreciation for 3 pumps.

3rd Year, run Pumps 1 and 2 evenly, taking a tax break for capital depreciation for 3 pumps.

4th Year, run all 3 Pumps evenly, taking a tax break for capital depreciation for 3 pumps.

....

Run until Pump 1 fails (most wear), replace it and continue even rotation.

...

Run until Pump 2 fails (next most wear), replace it and continue even rotation

....

Run until Pump 3 fails, replace it, and continue even rotation.

...

Repeat cycle.

Hopefully, the pumps will fail in different years, allowing the accounts time to recover from the shock. But you got Murphy's Law to contend with, so Pump 3 might actually fail first!

In years with sympathic tax laws, you may get Accelerated Depreciation, which makes buying new equipment effectively cost less. So instead of contiuning to run an old pump, it may be cheaper overall to buy a new one, if you can claim enough Depreciation the first year to pay for it. In years of increasing business taxes (like 2011), you may have to skip the replacement altogether. Our screwed-up convoluted tax code is one reason businesses are not expanding.

Now write a program for the above!

Last edited:

OkiePC

Lifetime Supporting Member

I agree with Lanice on this for the purpose of trying to maintain even wear.

On the other hand there are good reasons to rotate pumps, like to prevent sludge or other material from caking up in them, or rusting out the bearings, by sitting idle for weeks...

As for dealing with taking one of them out of the rotation, that is likely going to be an issue. To do that, the basic premise is the same, but the outputs become indirect. "Run Pump 1 and Pump 2" then has to be programmed to mean "Run the pumps presently assigned to positions 1 and 2".

On the other hand there are good reasons to rotate pumps, like to prevent sludge or other material from caking up in them, or rusting out the bearings, by sitting idle for weeks...

As for dealing with taking one of them out of the rotation, that is likely going to be an issue. To do that, the basic premise is the same, but the outputs become indirect. "Run Pump 1 and Pump 2" then has to be programmed to mean "Run the pumps presently assigned to positions 1 and 2".

OkiePC

Lifetime Supporting Member

Let me rephrase:

Run pump 1 when the .acc = 0 or 2

Run pump 2 when the .acc = 0 or 1

Run pump 3 when the .acc = 1 or 2

One OTE per pump output address...

Run pump 1 when the .acc = 0 or 2

Run pump 2 when the .acc = 0 or 1

Run pump 3 when the .acc = 1 or 2

One OTE per pump output address...

Bearsgone,

Instead of putting two OTE in parallel on your rungs, use one OTE (B3:4/8, B3:4/9, and B3:4/10 only used for 1 OTE each), but put two EQU statements in parallel at the input side of Rungs 2, 3, and 4, each with one of the comparisons to be made for each pump.

If you make the above change, then you will need to change Rungs 9 and 10 also (removing the left-side parallel branches, leaving only one B3:4 input for A on Rung 9, and one for B on Rung 10.

Instead of putting two OTE in parallel on your rungs, use one OTE (B3:4/8, B3:4/9, and B3:4/10 only used for 1 OTE each), but put two EQU statements in parallel at the input side of Rungs 2, 3, and 4, each with one of the comparisons to be made for each pump.

If you make the above change, then you will need to change Rungs 9 and 10 also (removing the left-side parallel branches, leaving only one B3:4 input for A on Rung 9, and one for B on Rung 10.

Last edited:

Paul B

Member

Lancie1: that was an interesting post you made above, post #10 in this thread. I have not seen that stated before. Made me think about the 50-something exhaust fans that will all accumulate the same hours in a program I did last year...

Always learning something when I visit here!

Always learning something when I visit here!

Similar Topics

hi guys, i would like to put an running hour counter in the program of a ml1200 plc to be viewed on a hmi, but i am not to sure what instruction...

- Replies

- 36

- Views

- 18,111

I have a little bit of experience with Allen-Bradley. I have a Micrologix 1500 (RSLogix 500) and a PanelView Plus 7 (FactoryTalk View Studio ME)...

- Replies

- 2

- Views

- 82

buen dia.

tengo una falla al pasar los tags de mi plc SLC 5 0/4 a mi panel me aparece un error Problem writing value " " to item <tag name>...

- Replies

- 1

- Views

- 73

Will someone please convert this logic to pdf?

- Replies

- 2

- Views

- 119

Hello, Haven't been on in a while.

I need to generate a bit level pdf of the I/O for RSLogix 500. I can generate a report but it just shows the...

- Replies

- 1

- Views

- 148