Hi guys,

I'm a automation student here in Norway, and I have just become an apprentice at a fish processing plant.

One of my first tasks is to replace the control system on a central mounted high preassure washing system. There are 10 pumps that are each controlled by a contactor. The pumps supply several washing stations around the plant.

The preassure is read by a 4-20mA preassure sensor.

I need to regulate the preassure. That's not a big problem. The part i find diffucult is that i want all the pumps to alternate so that each pump wear equal.

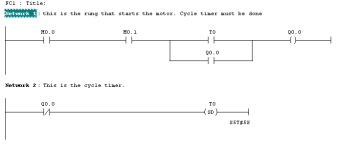

I have tried several "tactics" but all seem to end up with way to much logic (big program).

My experience at school is limited to Saia-Burgess PLCs (FBD). At this project i use a Omron CJ1 PLC (ladder logic).

Anyone have some hints to how to write this program?

Regards,

Patrick.

I'm a automation student here in Norway, and I have just become an apprentice at a fish processing plant.

One of my first tasks is to replace the control system on a central mounted high preassure washing system. There are 10 pumps that are each controlled by a contactor. The pumps supply several washing stations around the plant.

The preassure is read by a 4-20mA preassure sensor.

I need to regulate the preassure. That's not a big problem. The part i find diffucult is that i want all the pumps to alternate so that each pump wear equal.

I have tried several "tactics" but all seem to end up with way to much logic (big program).

My experience at school is limited to Saia-Burgess PLCs (FBD). At this project i use a Omron CJ1 PLC (ladder logic).

Anyone have some hints to how to write this program?

Regards,

Patrick.