I am trying to flowchart and write a RS 500 logic program for my plc class. The problem is to have an auger that dumps oatmeal on a conveyor put the oatmeal in a box that sits at the end of the conveyor. We will expand the process in later class sessions but currently the conveyor must start before the auger and it takes 3 seconds to fill the box. The estop must shut down the entire system but the stop button must retain the time of the auger and the conveyor must run for 3 seconds to empty what product is on the conveyor. Once the start button is pushed the process has to restart and the remaining time on the augers 3 seconds to put product on the conveyor must start from the stopping point to resume filling the box. I am using OTL and OTU outputs and rto timer to keep track of the time auger runs until stop or estop is activated. I am using a timer to run the conveyor 3 seconds if stop is activated. My problem is figuring out how to use the stop and estop correctly to enable otu and activate timer on conveyor for 3 seconds. As well as estop to stop everything immediately. I would like to flow chart this properly but cant seem to get the stop and estop to unlatch properly and things to reset properly.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RS 500 Logic

- Thread starter jd2325

- Start date

James Mcquade

Member

post again and attach a copy of your work.

we will give you suggestions and let you think things through.

What i do is to go offline and then toggle each bit in the logic. this will set the wheels in motion for you.

its long and time consuming. fut it gets the job done.

regards,

james

we will give you suggestions and let you think things through.

What i do is to go offline and then toggle each bit in the logic. this will set the wheels in motion for you.

its long and time consuming. fut it gets the job done.

regards,

james

I dont have RS Logic 500 on my computer. I have to do everything at school and save onto memory stick. Unfortunately I cannot open my work at home. Looking for a way to get really good at PLC programming. I find this interesting and it seems all employers first question is do you know PLC's.

Thanks again for your help I will try to scan my program and post it

Jim Dalton

jd2325

Thanks again for your help I will try to scan my program and post it

Jim Dalton

jd2325

Ron Beaufort

Lifetime Supporting Member

if you have a current copy of your work (as an RSS file) on a memory stick now, just post that here on the forum (as an attachment to this thread) ... (note that you'll have to zip it first) ... someone may be able to open the file and "print" it to a PDF that we can help you with ...

also - tell us what hardware you're working with at school ... there is a free legal download copy of RSLogix500 available ... it only works for MicroLogix 1000 and 1100 processors - but it MIGHT be helpful for you to practice navigation skills "offline" with at home ... also - sometimes it's possible to Copy-and-Paste the rungs from one version of the software to another ...

welcome to the forum ... and good luck with your studies ...

also - tell us what hardware you're working with at school ... there is a free legal download copy of RSLogix500 available ... it only works for MicroLogix 1000 and 1100 processors - but it MIGHT be helpful for you to practice navigation skills "offline" with at home ... also - sometimes it's possible to Copy-and-Paste the rungs from one version of the software to another ...

welcome to the forum ... and good luck with your studies ...

Last edited:

RS Logic 500

Ron, you said that there is a way to download a legal RS Logic 500. We use A&B 1000 processors in our lab at school but I cant do any work at home. If you would please let me know where to get this download I would be appreciative. Thank you for your help I am trying to become a programmer due to the fact I have had 3 back surgeries and still have more to come, consequently I need to use my brains rather than braun to make a living. This is my second semester of PLC training and my instructor is a brilliant programmer but with the resources at the school he can only do so much. I am looking to take a third semester and then I need to find out how to become extremely proficient in the PLC field. If you have any advice for highly advanced training I would love to hear about it.

Thank You,

Jim Dalton

jd2325

Ron, you said that there is a way to download a legal RS Logic 500. We use A&B 1000 processors in our lab at school but I cant do any work at home. If you would please let me know where to get this download I would be appreciative. Thank you for your help I am trying to become a programmer due to the fact I have had 3 back surgeries and still have more to come, consequently I need to use my brains rather than braun to make a living. This is my second semester of PLC training and my instructor is a brilliant programmer but with the resources at the school he can only do so much. I am looking to take a third semester and then I need to find out how to become extremely proficient in the PLC field. If you have any advice for highly advanced training I would love to hear about it.

Thank You,

Jim Dalton

jd2325

Mickey

Lifetime Supporting Member

Ron, you said that there is a way to download a legal RS Logic 500. We use A&B 1000 processors in our lab at school but I cant do any work at home. If you would please let me know where to get this download I would be appreciative. .

Thank You,

Jim Dalton

jd2325

See link below under software. Also Free Emulation Software.

http://www.ab.com/programmablecontrol/plc/micrologix/downloads.html

Thanks for the tip I downloaded the software and tried to download RS Linx Lite and it told me I could not open the file and RS Logic 500 needs Linx. You gotta love A&B downloaded off their website and it wont run. Have you ever heard of this problem.

sthompson

Lifetime Supporting Member + Moderator

Thanks for the tip I downloaded the software and tried to download RS Linx Lite and it told me I could not open the file and RS Logic 500 needs Linx. You gotta love A&B downloaded off their website and it wont run. Have you ever heard of this problem.

You do not need RSLinx to Edit and Review your PLC Program Offline. It is only required to go Online with the Processor. Which you probably won't be doing at home.

Stu.....

Hey, Jim, and welcome to the forum.

You can make flowcharts without RSLogix, and I think that is what your instructor wants you to do FIRST.

Then the program will be much easier. The flowchart wil serve as a roadmap for your program.

About your EStop that shuts everything down: This is known as a System Stop. The way you do that is you have a master relay that is energezied by a System Start pusbutton. Then if you push Emergency Stop (Estop), the master relay deenergizes and each and every other motor (which will have a contact from the master relay) will stop also.

You can make flowcharts without RSLogix, and I think that is what your instructor wants you to do FIRST.

Then the program will be much easier. The flowchart wil serve as a roadmap for your program.

About your EStop that shuts everything down: This is known as a System Stop. The way you do that is you have a master relay that is energezied by a System Start pusbutton. Then if you push Emergency Stop (Estop), the master relay deenergizes and each and every other motor (which will have a contact from the master relay) will stop also.

Jim,

I would not use Latch and Unlatch for your first program. These are not the best choices for beginners to use to control motors, unless there is some compelling reason to use them.

Often you can get a motor Latched on, with no way to turn it off. It is much better to use a seal-in contact to hold the motor on until something (loss of power, stop button, other switch) causes it to drop out.

I would not use Latch and Unlatch for your first program. These are not the best choices for beginners to use to control motors, unless there is some compelling reason to use them.

Often you can get a motor Latched on, with no way to turn it off. It is much better to use a seal-in contact to hold the motor on until something (loss of power, stop button, other switch) causes it to drop out.

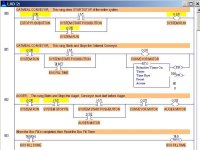

I may have not understood exactly what you need, but here is one shot at it. This is probably not complete, but maybe it will give you some ideas about what is needed.My problem is figuring out how to use the stop and estop correctly to enable otu and activate timer on conveyor for 3 seconds. As well as estop to stop everything immediately.

Last edited:

I may have not understood exactly what you need, but here is one shot at it. This is probably not complete, but maybe it will give you some ideas about what is needed.

Start with the E-Stop button - should be Normally Cloaed.

Hmmmm....

Rguimond,

If you are referring to the XIC Input instruction I:1/0 on Rung 0, then I am going to say that if the physical EStop pushbutton is "Normally Closed", then this PLC instruction is correct as is.

Rguimond,

If you are referring to the XIC Input instruction I:1/0 on Rung 0, then I am going to say that if the physical EStop pushbutton is "Normally Closed", then this PLC instruction is correct as is.

Similar Topics

Anyone have a sample program to move a Kinetics single axis servo in Studio 5000? Any help is appreciated.

- Replies

- 1

- Views

- 745

Hello all,

I came across the logic of the attached photos where the programmer is using an analog value to write on two inputs.

My guess is that...

- Replies

- 10

- Views

- 2,483

how to delete password protection from rs logic500 (plc is micrologic 1400)

i kinow the plc but i want to remove password protection.

what is the...

- Replies

- 3

- Views

- 1,613

Dear friends,

i wand to creat a program in which my motor runs 6 month in every year. Means motor on 6 months and ofer...

- Replies

- 12

- Views

- 4,506

So I have to encoders with A,B and Z pulse 360 encoder wired up to A0+, B0+ and Z0+ and the - pulses wired to common 24vdc. I can see the inputs...

- Replies

- 0

- Views

- 1,036