rpoet

Member

Hello All,

I have a pneumatics question for the group; I need the behavior of a single-acting cylinder with spring return, but I need more force than the spring return can provide.

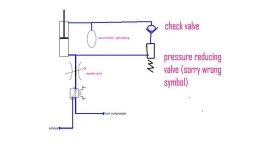

I'm thinking of creating a "spring" by plumbing the rod-end port of a double-acting cylinder to a sealed and pressurized (with air) reservoir to act as the return spring. I would fine-tune the return pressure by adjusting the air in the reservoir. I realize I will need to periodically check the pressure and provide a means of introducing makeup air - probably a Schrader valve - to account for losses around the cylinder's seal, but that's totally do-able.

The cylinders involved are small - 3/4" bore and 6" stroke, so the reservoir can probably be little larger than a pop can. It's a long story, but suffice to say I can only run one air line to each location. Control will be handled by 2-way, 3-port solenoids, mounted remotely.

Thoughts?

Thanks,

-rpoet

I have a pneumatics question for the group; I need the behavior of a single-acting cylinder with spring return, but I need more force than the spring return can provide.

I'm thinking of creating a "spring" by plumbing the rod-end port of a double-acting cylinder to a sealed and pressurized (with air) reservoir to act as the return spring. I would fine-tune the return pressure by adjusting the air in the reservoir. I realize I will need to periodically check the pressure and provide a means of introducing makeup air - probably a Schrader valve - to account for losses around the cylinder's seal, but that's totally do-able.

The cylinders involved are small - 3/4" bore and 6" stroke, so the reservoir can probably be little larger than a pop can. It's a long story, but suffice to say I can only run one air line to each location. Control will be handled by 2-way, 3-port solenoids, mounted remotely.

Thoughts?

Thanks,

-rpoet