Tim, there are a couple of things I don't like on your diagram, some of which are just personal preference.

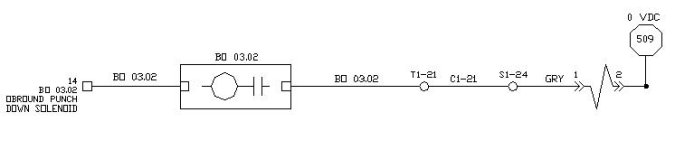

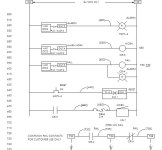

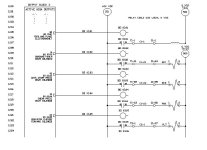

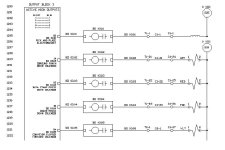

1) You show the coil and contact in one block, which is confusing. They should be separate items, with the rung of the contact cross referenced on the rung with the coil. This would be in conformance with common practice and the old JIC standards.

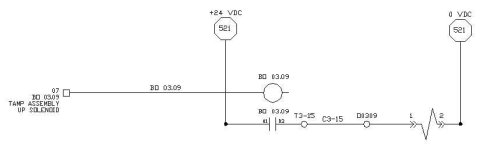

2) I ASSUME that BO 03.02 is a source output on the PLC that pulls in the relay. That should be clear. Some guys like to put all outputs on a given I/O card in one block, but I break them up so the logic with the interlocks is obvious

3) I personally don't like using the output to deignate the relay - you can have several devices (like a relay and a pilot light) tripped by the same output. I still use the old JIC format of CR-#### and a separate description of the function

4) I am assuming that circles represent field terminals and octagons internal terminals. That is OK if you have a legend denoting that.

5) I maintain the same wire number on all devices that have the same electrical state. Going through a terminal block shouldn't change the wire number

7) I assign the wire numbers based on the rung number. I number rungs in increments of 10, and for example the first wire number on a rung is 710, the second can be 711 or 715 or whatever you want. I don't often have more than three or four wire numbers per rung. This aids troubleshooting, since it is easy to locate the wire on the drawings.

Attached is a diagram I pulled at random - blast away guys!