rlawson

Member

I've browsed, searched and read almost every post dedicated to PID on this forum. It is amazing just how much knowledge can be gained by reading other users posts. I would like to mention Peter and Ron specifically for their contributions to this forum helping to educate the rest of us. With the information that I have learned here I have implemented quite a few projects sucessfully using PID for motion and position control.

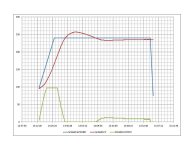

I have downloaded a few of the PID simulator excel files and have enjoying toying with them. But one thing that I am looking for is an excel PID simulator for temperature control. I am getting ready to do an upgrade of a batch baking oven using a Directlogic D260 PLC. I haven't really modeled the existing system yet, but I would like to play around with various settings using a simulator. I have used this PLC many times utilizing PID for dancer control on various wire drawbenches and winder takeups. If Ron or Peter already has this spreadsheet I would very much like to see it.

I have downloaded a few of the PID simulator excel files and have enjoying toying with them. But one thing that I am looking for is an excel PID simulator for temperature control. I am getting ready to do an upgrade of a batch baking oven using a Directlogic D260 PLC. I haven't really modeled the existing system yet, but I would like to play around with various settings using a simulator. I have used this PLC many times utilizing PID for dancer control on various wire drawbenches and winder takeups. If Ron or Peter already has this spreadsheet I would very much like to see it.