Hello everybody.

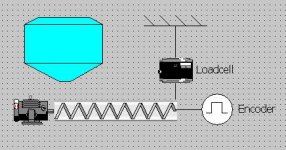

Can I calculate flow of dust to be pelletized with a configuration shown in the picture? We will take the loadcell signal with a Siwarex and calculate the speed of conveyor via encoder. I thought of a formula like,

Flow = Mass X Speed / Coefficent [kg X m / s]

Have you ever calculated the flow like this before and what should I check with this system? Since we calculated the overall moment of the conveyor what will be the effect of the material which havent arrived at the adge of the conveyor where the loadcell will be attached? To make my calculation more accurate which way should I go?

In the end I am trying to simulate a mass flowmeter with loadcell and a encoder. What will be the accuracy of the calculation?

Thanks...

Can I calculate flow of dust to be pelletized with a configuration shown in the picture? We will take the loadcell signal with a Siwarex and calculate the speed of conveyor via encoder. I thought of a formula like,

Flow = Mass X Speed / Coefficent [kg X m / s]

Have you ever calculated the flow like this before and what should I check with this system? Since we calculated the overall moment of the conveyor what will be the effect of the material which havent arrived at the adge of the conveyor where the loadcell will be attached? To make my calculation more accurate which way should I go?

In the end I am trying to simulate a mass flowmeter with loadcell and a encoder. What will be the accuracy of the calculation?

Thanks...

Last edited: