hello there,

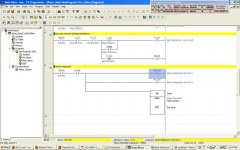

i am facing some programming problem in one of my system.

logic is:

in a roller conveyor there is a limit switch in the middle. so the system should work like- the roller is altime on but when a board is touching the limit the roller will stop and after stopping 2 pusher ( solenoid valve) will push the board to be allign with the conveyor and solenoid will retract it self and roller will start again.

i should mention that i have used NO type limit switch and board will be touching the limit switch all the time because boards very close. so i have used one shot for the limit switch so it will turn on one time with each borad touching it. after that i cant make the cycle to start the conveyor.

any type suggestions is welcome

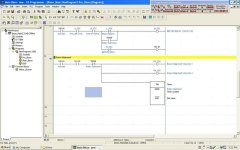

i am facing some programming problem in one of my system.

logic is:

in a roller conveyor there is a limit switch in the middle. so the system should work like- the roller is altime on but when a board is touching the limit the roller will stop and after stopping 2 pusher ( solenoid valve) will push the board to be allign with the conveyor and solenoid will retract it self and roller will start again.

i should mention that i have used NO type limit switch and board will be touching the limit switch all the time because boards very close. so i have used one shot for the limit switch so it will turn on one time with each borad touching it. after that i cant make the cycle to start the conveyor.

any type suggestions is welcome