Hi to all. I have a 2090-DSD-005X-DN Ultra 3000i servo drive that I have been experiencing with. I have set up communications with the drive via Device Net and a 1756-DNB DeviceNet Scanner(located in slot 1). I'm using Instance Id 9 output assy. and Instance Id 12 Inputs assy.

*In UltraWare I'm using Indexing as my operation Mode.

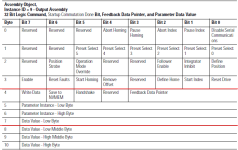

The issue I'm dealing with is I want to be able to write to parameter 358 Index 0 Distance/Position. I have read the manual Publication-RM004B-EN-E but I don't know how to set this up in my program Logix 5000. I have set up a similar program to the one I found from Ab's site but its for a CompacLogix Processor I'm using Logix 5550. Here is a snap shot of the logic.

Can anyone please help me in achieving this.

Thank You.

*In UltraWare I'm using Indexing as my operation Mode.

The issue I'm dealing with is I want to be able to write to parameter 358 Index 0 Distance/Position. I have read the manual Publication-RM004B-EN-E but I don't know how to set this up in my program Logix 5000. I have set up a similar program to the one I found from Ab's site but its for a CompacLogix Processor I'm using Logix 5550. Here is a snap shot of the logic.

Can anyone please help me in achieving this.

Thank You.