mmarinr

Member

Hi guys!

PLC SLC5/03

PV 550 2711-K5A2 ser H frn 4.46

So here is the problem...

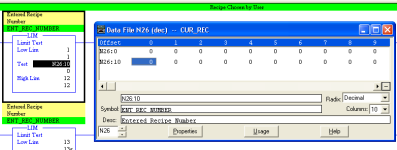

I'm trying to set a recipe manager screen on my PV.

I used the Increment/Decrement Entry option for scrolling between the recipes.

I asigned an INT to the tag, so that the PLC would recognize the number and load the data for each recipe.

The problem is the PLC is not recognizing the numbers. Foe example, I assigned N26:10 as my INT and the same for the tag.

I scroll up on the PV, let's say to 5, but the PLC will keep showing a value of 0 for N26:10.

To make it easier for the operator, I set the limits of my INT from 1 to 60, with an initial value of 1 for N26:10. But once again, the PLC will keep showing a 0.

Pics for the tag on PanelBuilder and a screenshot of the online PLC

Somebody knows if I'm doing anything wrong? Please let me know!

PLC SLC5/03

PV 550 2711-K5A2 ser H frn 4.46

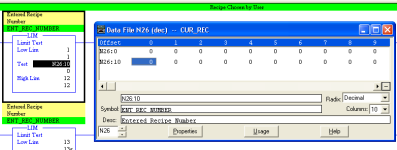

So here is the problem...

I'm trying to set a recipe manager screen on my PV.

I used the Increment/Decrement Entry option for scrolling between the recipes.

I asigned an INT to the tag, so that the PLC would recognize the number and load the data for each recipe.

The problem is the PLC is not recognizing the numbers. Foe example, I assigned N26:10 as my INT and the same for the tag.

I scroll up on the PV, let's say to 5, but the PLC will keep showing a value of 0 for N26:10.

To make it easier for the operator, I set the limits of my INT from 1 to 60, with an initial value of 1 for N26:10. But once again, the PLC will keep showing a 0.

Pics for the tag on PanelBuilder and a screenshot of the online PLC

Somebody knows if I'm doing anything wrong? Please let me know!