TimothyMoulder

Member

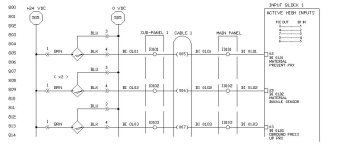

A while ago, we hashed about how to handle interposing relays on a schematics diagram. Now, I wanted to get some feedback on documenting inputs.

Below is how I handle it right now. A few specific things I'm looking for :

1. There is a 16-conductor cable running between the sub-panel and the main panel. The conductors are marked at both ends with the input numbers. How important is it to document the specific conductor number? What if the conductors are separated by colors instead of numbers? What if multiple cables are run between the same panels?

2. If the conductors should be specified (I'm leaning that direction), what is a good way to do so? In the past I used "C1-xx" designations, but this seemed to produce confusion.

Thanks!

TM

Below is how I handle it right now. A few specific things I'm looking for :

1. There is a 16-conductor cable running between the sub-panel and the main panel. The conductors are marked at both ends with the input numbers. How important is it to document the specific conductor number? What if the conductors are separated by colors instead of numbers? What if multiple cables are run between the same panels?

2. If the conductors should be specified (I'm leaning that direction), what is a good way to do so? In the past I used "C1-xx" designations, but this seemed to produce confusion.

Thanks!

TM

Last edited: