Hello

To prevent over-heating of motor supplyer rate them for 3-4 start per hours of full load and direct online starting...

To respect that, a very basique plc logic can freeze any restart for 15-20minutes (3x20minutes=3start max per hour )

This is a pain when the motor ran for a long time already cooled down from it's last start while we still need to wait the maximum time...

I have seen relay/controler with an evolutive logic taking count of how often the motor get started in the same hours etc permitting to restart it just after few minutes for the first attempt and increasing the delay for the second etc...

Do someones know how this logic is based ?

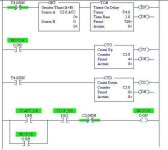

I'm looking to a logic decreasing the 1200 secondes locking time as long as the motor run

20minutes:

300sec + (900sec-1sec each 1or2 sec of continius runtime)

Ranging from 5 to 20 minutes...

Is there any easier way to do that or other parameter to take into account?

By the way i have seen programmer that never goes inside an eletrical room to see blown device, starting and stoping good horsepower motor many times under a very short period doing test like in the lab!

To prevent over-heating of motor supplyer rate them for 3-4 start per hours of full load and direct online starting...

To respect that, a very basique plc logic can freeze any restart for 15-20minutes (3x20minutes=3start max per hour )

This is a pain when the motor ran for a long time already cooled down from it's last start while we still need to wait the maximum time...

I have seen relay/controler with an evolutive logic taking count of how often the motor get started in the same hours etc permitting to restart it just after few minutes for the first attempt and increasing the delay for the second etc...

Do someones know how this logic is based ?

I'm looking to a logic decreasing the 1200 secondes locking time as long as the motor run

20minutes:

300sec + (900sec-1sec each 1or2 sec of continius runtime)

Ranging from 5 to 20 minutes...

Is there any easier way to do that or other parameter to take into account?

By the way i have seen programmer that never goes inside an eletrical room to see blown device, starting and stoping good horsepower motor many times under a very short period doing test like in the lab!