chriswarrn

Member

- Join Date

- Dec 2003

- Posts

- 24

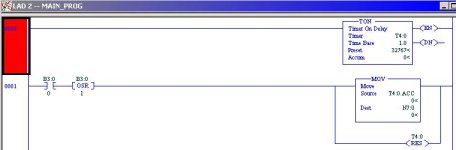

I'm trying to write a program to measure the Feet Per Minute of a conveyor. I would like to display the FPM at least once every 2 seconds or so. I want to use a prox switch to sense the teeth on the sprocket. Each leading-edge pulse of the prox (the length of each prox pulse depends on the FPM of the conveyor) will move the accumulated value of a free-running timer to an address, and then reset the timer. Then I'll just do a little math and display the measured FPM.

Maybe I'm trying to do this the hard way, but I can't figure out how to move the timer value before the timer gets reset. The timer reset command is always performed before the MOV. The address I'm using always reads zero.

ANY ideas will be gr8ly appreciated.

Maybe I'm trying to do this the hard way, but I can't figure out how to move the timer value before the timer gets reset. The timer reset command is always performed before the MOV. The address I'm using always reads zero.

ANY ideas will be gr8ly appreciated.