wildswing

Member

Hey fellas,

It's been a very long time since I worked on our PV600 terminals with PanelBuilder and have a question. I haven't had a chance to dig into it yet, so maybe I'm over thinking this and there's a simple answer.

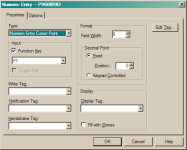

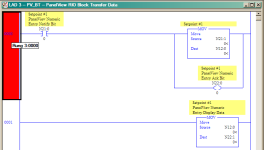

I have a PV600 set up as a remote IO rack for a PLC5. The PLC5 is set up with a BTR/BTW pair to handle integers for operator input and displays. In the PV I have numeric inputs which are read by the PLC by the BTR. This setup works just fine for purely operator inputs. Now they want me to manipulate one specific input value in the PLC logic, outside the operator's control. The problem is that I cannot change the value of that integer because the BTR keeps overwriting it.

Is there an alternative way to get that number from the PV600 to the PLC outside of the BTR like writing directly to an N7 word that's outside the block transfers touch or am I stuck using the BTR? Would be nice to have a means to input a number on the PV but only have it write once to the PLC. If I must use the BTR to get that numeric input from the PV, then I'll have to do some fancier logic to use either the PV value or my new value.

Any help or advice you may have would be very much appreciated.

It's been a very long time since I worked on our PV600 terminals with PanelBuilder and have a question. I haven't had a chance to dig into it yet, so maybe I'm over thinking this and there's a simple answer.

I have a PV600 set up as a remote IO rack for a PLC5. The PLC5 is set up with a BTR/BTW pair to handle integers for operator input and displays. In the PV I have numeric inputs which are read by the PLC by the BTR. This setup works just fine for purely operator inputs. Now they want me to manipulate one specific input value in the PLC logic, outside the operator's control. The problem is that I cannot change the value of that integer because the BTR keeps overwriting it.

Is there an alternative way to get that number from the PV600 to the PLC outside of the BTR like writing directly to an N7 word that's outside the block transfers touch or am I stuck using the BTR? Would be nice to have a means to input a number on the PV but only have it write once to the PLC. If I must use the BTR to get that numeric input from the PV, then I'll have to do some fancier logic to use either the PV value or my new value.

Any help or advice you may have would be very much appreciated.