Hello All,

I'm new here so pls bear with me.

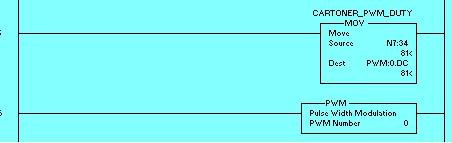

I have an AB1500 PLC and I am trying to use the PWM or PTO function to control the speed of a small 12V dc motor. I have the Instruction set manual, but cannot get the hand of how to program these functions effectively.

I would appreciate any help, ideally a ladder program using any or both of these instructions so that I can use them to learn how to program these functions.

Tks in advance!

I'm new here so pls bear with me.

I have an AB1500 PLC and I am trying to use the PWM or PTO function to control the speed of a small 12V dc motor. I have the Instruction set manual, but cannot get the hand of how to program these functions effectively.

I would appreciate any help, ideally a ladder program using any or both of these instructions so that I can use them to learn how to program these functions.

Tks in advance!