I have a motor drive, which has 7 preset speed settings, selected via a 3-bit input (ie 001 = speed one, 010 = speed two etc etc).

The drive is connected to a Siemens S7-300 CPU312C.

Control of the drive is via a panel that includes "Speed Up" and "Speed Down" buttons and a 7 x LED bar that displays the current speed. (also connected to the PLC)

Can anyone advise the best way to tackle the handling of the speed changes please?

An example of the sequence would be:

* Drive is currently on Speed #1 (PLC Outputs are 0,0,1), First LED only is illumintated on the panel

* User presses "Speed UP".

* First & Second LEDs now illuminate.

* PLC Output to drive changes to 0,1,1 to reflect speed TWO

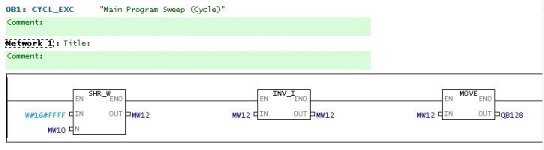

My guess is that I need a function that adds 1 to an integer in memory with each speed increase (and -1 for decrease).

What I don't know how to do is output that integer as binary to the PLC outputs.

Also Don't know how to output 1-7 +24v signals (to LEDs) based on what the number is (1-7).

Can anyone fill in the gaps in my knowledge please!! Thanks a lot

The drive is connected to a Siemens S7-300 CPU312C.

Control of the drive is via a panel that includes "Speed Up" and "Speed Down" buttons and a 7 x LED bar that displays the current speed. (also connected to the PLC)

Can anyone advise the best way to tackle the handling of the speed changes please?

An example of the sequence would be:

* Drive is currently on Speed #1 (PLC Outputs are 0,0,1), First LED only is illumintated on the panel

* User presses "Speed UP".

* First & Second LEDs now illuminate.

* PLC Output to drive changes to 0,1,1 to reflect speed TWO

My guess is that I need a function that adds 1 to an integer in memory with each speed increase (and -1 for decrease).

What I don't know how to do is output that integer as binary to the PLC outputs.

Also Don't know how to output 1-7 +24v signals (to LEDs) based on what the number is (1-7).

Can anyone fill in the gaps in my knowledge please!! Thanks a lot