ceilingwalker

Lifetime Supporting Member

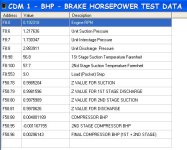

Good day all. I have just recently started checking out all the "bell's and whistle's" with the RSLogix 500 and would like to know what a couple items on the menu tree are for. First is the "CDM", what is it used for and could you please give an example. Also are the "Custom Graphical Monitors" and "recipe monitors". As before, what they are used for and an example. I'm going to search for info online but a lot of times you folks are much easier to learn from than Rockwell Software Books. Thanks much.