You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How many HMI's can connect to compactlogix

- Thread starter rigicon

- Start date

The Plc Kid

Member

Both you have listed will support 100 connections but the built in ethernet port only supports 32 and you don't want to tap that out or you will have comms issues and you will not be able to go online.

A HMI can consume 1 or more conections depending on the HMI and the size and data used by the application. You may have issues way before 32 depending on the RPI of the HMI systems in question.

A HMI can consume 1 or more conections depending on the HMI and the size and data used by the application. You may have issues way before 32 depending on the RPI of the HMI systems in question.

Personally, I think you are exciting big time. Typically I only like 2-4 clients talking to a logix processor. The comms can strain the processor and cause lag, or unexpected results. BUT, that largely depends on how much data you are requesting, how efficient the code is written and your comms settings in your HMI.

You may want to consider an opc server, this would be a new computer that talks directly to the PLC, and the HMI's talk directly to the computer. Downside, if you need to reboot the OPC server, all your HMI's go down.

You may want to consider an opc server, this would be a new computer that talks directly to the PLC, and the HMI's talk directly to the computer. Downside, if you need to reboot the OPC server, all your HMI's go down.

Thanks all. It is a 1769-L32E I spoke to Rockwell they suggested to look at the comms load and make sure it is less than 70%(this was hard as it was flickering and not all comm actions were taking place) and I increased the comms(system) cpu load to 30% from 20%.

I have optimised the code and some HMI's only have 9 or 11 tags the rest are to a Proserver setup(Proface-OPC).There are 4 HMI's which have a 100-112 tags. It seems fine so I am leaving it for now. It is quiet a bit of work to route it all through the OPC - Hind-sight what a beautiful thing Eh - already wrote the code then I started to think about the comms load.

I have optimised the code and some HMI's only have 9 or 11 tags the rest are to a Proserver setup(Proface-OPC).There are 4 HMI's which have a 100-112 tags. It seems fine so I am leaving it for now. It is quiet a bit of work to route it all through the OPC - Hind-sight what a beautiful thing Eh - already wrote the code then I started to think about the comms load.

No Ethernet/IP IO only Ethernet/IP to the 17 HMI's and 3 32bit Input cards and 3 32bit Output cards but the compactlogix also talks via Devicenet to 3 ABB robots via a scanner module.

Yea interesting job been 9 months at it. Big system.

HMI talks to PLC to Robot and vice versa. Plus there is a SQL database controlling the whole thing via a Pro Server OPC Scada which also talks to HMI's and Compactlogix.

The PLC doesn't have any complicated logic only some compares and Devicenet coms nothing that would give it too much load.

It goes online very quickly and monitors superb whilst talking to all the HMI's and I regularly do online changes as they are in production.

Yea interesting job been 9 months at it. Big system.

HMI talks to PLC to Robot and vice versa. Plus there is a SQL database controlling the whole thing via a Pro Server OPC Scada which also talks to HMI's and Compactlogix.

The PLC doesn't have any complicated logic only some compares and Devicenet coms nothing that would give it too much load.

It goes online very quickly and monitors superb whilst talking to all the HMI's and I regularly do online changes as they are in production.

Last edited:

It goes online very quickly and monitors superb whilst talking to all the HMI's and I regularly do online changes as they are in production.

Oh dear spoke too soon.It doesn't go online anymore too much going on.....

I have now made it 4 HMI's and the other 13 via computer OPC.

CPU at about 62% and goes online straight away.

Just as a pecaution to anyone thinking of attaching too many HMI's to one PLC

Thanks all. It is a 1769-L32E I spoke to Rockwell they suggested to look at the comms load and make sure it is less than 70%(this was hard as it was flickering and not all comm actions were taking place) and I increased the comms(system) cpu load to 30% from 20%.

I have optimised the code and some HMI's only have 9 or 11 tags the rest are to a Proserver setup(Proface-OPC).There are 4 HMI's which have a 100-112 tags. It seems fine so I am leaving it for now. It is quiet a bit of work to route it all through the OPC - Hind-sight what a beautiful thing Eh - already wrote the code then I started to think about the comms load.

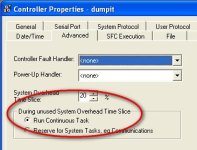

Depending on the firmware revision of the controller, you can increase the System Overhead TimeSlice value way more, but only if you have the option to release unused system time back to the continuous task (i think it came in with version 16).

Yea had it at 35% still PLC was 90-100%

Then shot it up to 45% couldn't get online to see the %

I understand the 32 CIP s can connect to 32 HMI's but if the RPI is high then I think it dedicates more CIP s to a particular HMI.

Some of the HMI's only had 4 bits to talk to PLC.

Other option is to get another comms card in the rack and split the comms.

Then shot it up to 45% couldn't get online to see the %

I understand the 32 CIP s can connect to 32 HMI's but if the RPI is high then I think it dedicates more CIP s to a particular HMI.

Some of the HMI's only had 4 bits to talk to PLC.

Other option is to get another comms card in the rack and split the comms.

Phrog30

Member

Rockwell has an Ethernet IP Capacity Tool Utility that you can run to ensure you are safe. Also IAB has some built in checking tools. Two very useful tools when setting up networks. These items are really made for Rockwell products, but you can input the number of tags used which is generic for almost any HMI. Just my two pennies.

Rockwell has an Ethernet IP Capacity Tool Utility that you can run to ensure you are safe. Also IAB has some built in checking tools. Two very useful tools when setting up networks. These items are really made for Rockwell products, but you can input the number of tags used which is generic for almost any HMI. Just my two pennies.

Please tell more ! Where can I get these tools?

I have really streamlined the program so the tags are at minimum.

Phrog30

Member

Similar Topics

Hi to everybody !

I need to estimate (in term of hours of development), a HMI revamping and write a new software on a new hardware. Assuming...

- Replies

- 4

- Views

- 1,490

I have read that there is a maximum of ten thousand writes to an eprom within a plc or an hmi.

I have had a plc and hmi on my desk for over 2...

- Replies

- 3

- Views

- 1,947

Good Evening ,

We have a number of Powerflex 525 Drives . I took notice for years elsewhere and our plant , that our Powerflex 525 drive...

- Replies

- 0

- Views

- 636

Good Afternoon,

Just wondering , are many of you using SAP in your plants ? If so , is it difficult to learn ? Are there many training...

- Replies

- 10

- Views

- 1,418

It better to have too many instead of not enough right?

- Replies

- 26

- Views

- 2,884