Greetings ...

in a perfect world, Jamal would have been hired into a mid-sized to large company – one that could provide an experienced "Big Brother" to teach Jamal the ropes while working through this project ... in reality Jamal has been thrown into his present situation with no real work experience – with no help (except the forum) – and most importantly with insufficient time to get this project done ... I've already told him that I personally consider the deadline to be unrealistic – and frankly I don't think this story is going to have a happy ending ...

on a personal note: Wednesday, June 1 will mark the 20th anniversary of my marriage to the sweetest and most beautiful creature that I have ever met ... and my lovely little wife has promised to take me "away from it all" for a few days ... no computers – no internet – no PLCs ... and when I get back to town, I'll have MUCH work to do catching up on my own projects ... this means that I probably won't be able to help Jamal after this post ...

so ... I'm going to play "Big Brother" one more time and show Jamal how I think he should make the best use of whatever assistance the forum can offer ... one step is to ANSWER THE QUESTIONS that people ask ... specifically, do NOT just ignore the questions – by simply asking more questions of your own ...

here are some examples:

moggie, thank you for you reply ... let me show Jamal how to go about answering your questions ...

Just had a quick look, can you check your hardware config?

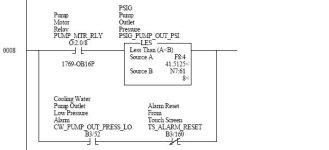

I'm not sure Jamal will know what you're asking ... the existing Allen-Bradley list is shown on page 4 of the PDF printout attached to Post #2 ... the "equivalent" list that the Siemens distributor provided is shown in Post #1 ...

as soon as possible, Jamal should look up the documentation for everything on the Siemens list and try to verify that the suggested modules actually will "match up" to the signals needed ...

How many Siemens cards of each type are being used as the RSLogix hardware shows 12 RTD inputs but your Siemens hardware list only shows 8 RTD inputs??

Jamal should repost the list IN FULL – this time giving the quantity of each part listed ... and this time he shouldn't use that artistic "center justify" trick – which just makes things hard to read ... engineers and programmers don't do things that way ... another suggestion: use Courier New font when making lists ... since all of the letters are the same width in that font, the part numbers on the list will tend to "line up" better and be easier to read ...

There are a lot of other differences in the hardware config?

I don't know ANYTHING about Siemens – so I'll have to assume (gosh I hate that word) that the differences you've spotted will become evident to Jamal as he researches the Siemens equipment list ...

The RSLogix pdf also refers to a Touch Screen But your Siemens list does not show this?(eg LAD 2 Line 004)

an excellent point ... I mentioned to Jamal in our phone conversation the fact that he might not have only the PLC to worry about ... specifically, he might (probably will?) have to tackle learning how to do an HMI application also ... (that deadline is looking more threatening all the time isn't it?) ...

Also the Siemens Hardware show 120V AC i/o not 24V DC ?

Jamal, you need to make sure that the voltages to be used on the new piece of equipment actually DO "match up" with the specifications of the modules the distributor has listed ... this is CRITICAL because if the wrong modules are ordered, the distributor is probably not going to accept their return ... your bo$$ will probably be stuck with extra modules – and forced to pay for the right ones ...

Have you a separate i/o list (schematics?) for the new machine?

Jamal, you need to answer this question with something like this (as examples):

(a) yes, I DO already have a full set of schematics for the new machine ...

(b) no, I do NOT have a set of schematics – I need to prepare a set myself ...

(c) no, someone else is working on the schematics – and I should receive them by Tuesday ...

(d) or something else along those lines ...

KalleOlsen ... thank you for your reply ...

Start with Step7 HWConfig.

Here is a lesson from the site I posted you yesterday:

http://www.automation.siemens.com/mc...a04_cpu315.pdf

Jamal, you need to look at that link and see what it can teach you ... Kalle isn't suggesting it just for kicks ...

Is this project so urgent that you don't have time to learn before you act?

unfortunately the answer to that one is probably "yes" ...

in my line of work I'm running into more and more of these horror stories every day ... with the economic downturn over the last several years, many systems integrators were forced to lay off their experienced workers ... those workers have since moved on to "other things" ... now that the economy seems to be picking up lately, the integrators are trying to power back up again by hiring kids fresh out of college ... the new hires are given little (often ZERO) training before being tossed into the deep end of the pool ... basically: "Here, get this project done by the deadline – or you're fired." ... the sad thing is that the old experienced greybeard workers are no longer around to provide any guidance to the newcomers ... in many ways, the forum has become the only "old experienced greybeard worker" available to help ...

You will get much better responses if you show what you have done and ask for comments. Now I have the feeling that you have promised something that you want us to do for you.

Kalle, I certainly respect your opinion – and I won't try to change it ... but I will say that when I talked with Jamal by phone yesterday, I did NOT get the impression that he wants us to do this for him ... on the contrary, I got the distinct impression that he really does want to do this for himself ... at this point, he just has no idea how to start a project like this – and then how to systematically carry the project through to its completion ...

personally, I don't think that Jamal intentionally promised something that he couldn't deliver ... more likely he got out of college needing a job – and a job was offered ... he took the job – and now he's finding out that there's quite a bit more to programming these little PLC thingies than he was led to believe by his college professors ...

the point I'd like to make is that I personally think that the kid actually COULD get this done (completely on his own) – IF (big IF) he had enough time to do it ... it's just that he doesn't have the time to learn the ropes ...

from JesperMP:

This does sound as a not-so-trivial task.

I'll agree ... personally I myself wouldn't even attempt to tackle it in the timeframe that's being allowed ... I know ZERO about Siemens – and I'd have to be EXTREMELY desperate to attempt learning it under these conditions ... (and I already know quite a bit about Allen-Bradley – which is NOT true of Jamal who still has a LONG way to go on that particular platform) ...

frankly I'd be terrified to be in Jamal's shoes ...

What is the deadline for all of this ?

my understanding is that he has about two weeks – MAYBE three ... Jamal, correct me if I'm wrong there ...

Additionally, 120VAC would be unlikely as a voltage level for i/o in EU. (Not totally unlikely though).

Jamal, you need to double-check that point - and then confirm that the machine will indeed be using 120VAC ... if that is NOT the case, then you need to make sure that the Siemens I/O modules will be the correct ones for the system being built ...

tell the forum what you find out about this point ... it's IMPORTANT ...

I have to ask if someone take care of the declaration of CE conformity as well ? There are several aspects to this declaration, the most important one is the machine safety.

Kalle brings up a VERY important issue ...

Jamal, who is doing the design of the actual machinery? ... hopefully, the conformity and the safety aspects of the project that Kalle has just raised are NOT part of your personal responsibilities ...

if this IS a part of your responsibilities then I'm afraid that your end of the pool just got a LOT deeper ...

from the unsolicited advice department ...

Jamal, suppose that you were my little brother, or a nephew, or a friend ... if you had asked me for my advice BEFORE you accepted this particular job – I would have advised you to seek employment elsewhere ... based on what I know of this trade, a kid fresh out of college can NOT be expected to just walk into a new job and pull off a project like this – at least without some sort of guidance ...

note that I am NOT saying that this can't be done ... I'm just saying that it can't be done WITHIN THE TIMEFRAME that's being allowed ...

as JesperMP has mentioned, this particular project would not be a "trivial" task even for someone with considerable experience behind them ...

in closing:

based on the impression that I got from talking with Jamal over the phone, he is friendly, he is polite, he is quite intelligent, he learns quickly, he's willing to work hard ...

and he desperately needs guidance on how to pull this project off ...

I've done all that I personally can ... Jamal, throw yourself on the mercy of the forum ... answer the questions that they ask of you ... and STAY IN THIS ONE SINGLE THREAD ...

I sincerely wish you the greatest success with your project – and with your future career ...

my work here is done ...