Hi!

A bit of background...I am new to PLCs, I have finished one program which is being used in production, but that only had one input, and two outputs so thought I would step it up a bit...

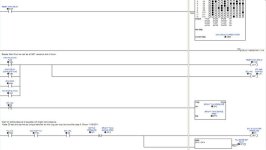

My next program has 4 inputs, and 10 or so outputs. I am using a drum sequencer for this.

I am using 2 analogue pressure transducers (4-20mA) and converting the signal to psi using scaling.

This is where I am stuck. At a specified step in the Drum I would like to take a sample reading of one of the pressures (Floating point) and store that pressure in memory, do some math on it and use it to compare against the other pressure input until the math condition is met, and then move on in the drum sequencer.

I can't figure out how to take a sample pressure, store it for a while and use it, then resample for the next time it will be used.

I am using a simple Click PLC which has limited instructions.

Any point in the right direction here would be greatly appreciated!

Cheers,

Simon.

A bit of background...I am new to PLCs, I have finished one program which is being used in production, but that only had one input, and two outputs so thought I would step it up a bit...

My next program has 4 inputs, and 10 or so outputs. I am using a drum sequencer for this.

I am using 2 analogue pressure transducers (4-20mA) and converting the signal to psi using scaling.

This is where I am stuck. At a specified step in the Drum I would like to take a sample reading of one of the pressures (Floating point) and store that pressure in memory, do some math on it and use it to compare against the other pressure input until the math condition is met, and then move on in the drum sequencer.

I can't figure out how to take a sample pressure, store it for a while and use it, then resample for the next time it will be used.

I am using a simple Click PLC which has limited instructions.

Any point in the right direction here would be greatly appreciated!

Cheers,

Simon.