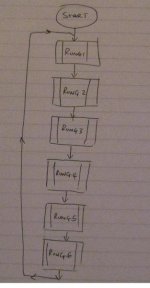

Robetere,

Good effort. Neat flowchart.

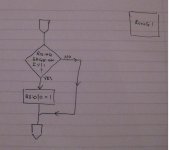

In real technical terms, your program "flow" does not return each loop or scan to the START block and re-latch B3:0/0.

Instead, once the timer is started, it is going all the way through the cycle, unless interrupted. Therefore, I think the 3 lines (Clockwise input Released, Anti Clockwise input Released, and Tilt Up Input Released) should feed back (not to Start) to the line on top of the Timer Finished block.

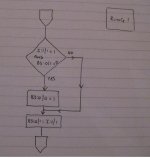

Even pickier, the 3 calibration functions are done serially, one after another, so maybe should be shown as such, with the end of the first one triggering the second one, and so on. If these functions need to be made parallel, then add two more indepencent timers.