So it would appear that that one-button question we all know and love is meant to serve as a speed bump? I finally got past that, and the next few challenges I got from my boss proved easy enough. I now have a bit of a grasp on counters, timers, and latching/unlatching functions. I was glad to hear him say things like "That's actually very good for a person with no programming experience" and "Okay, I'll send you another problem, I just need time, I wasn't expecting you to get that one that fast". I wouldn't claim to be an expert on PLCs, but these folks were cool enough to accept me for their co-op knowing I haven't had the classes that would make me an effective PLC programmer, and trusted that I would work hard to learn what I needed to know, and I have tried my best to learn, if for no other reason than to thank them for taking a chance on me, and to ensure that they will be willing to take on my class mates later on down the line.

I know, I know, "Cool Story, Bro" so permit me to cut to the chase. The difficulty of the PLC programming challenges I have been given has risen , but I can now look at the problems I am being given, and only certain parts of them are actual problems, the rest is "...And after you've solved for that, apply the tools you already have to write the rest of the ladder logic needed."

, but I can now look at the problems I am being given, and only certain parts of them are actual problems, the rest is "...And after you've solved for that, apply the tools you already have to write the rest of the ladder logic needed."

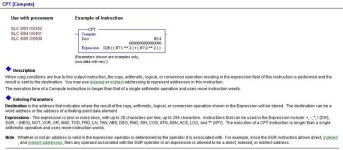

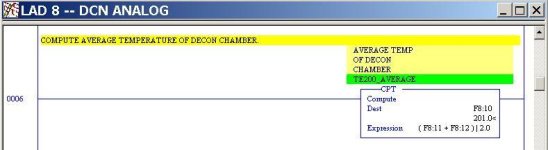

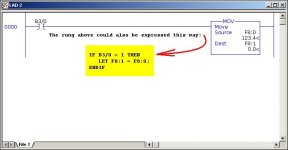

So here's my dilemma: I need to convert a temperature (In degrees Fahrenheit, and it's a decimal number) to Celsius. I already know the formula I'm going to use, and I have a rough idea how to implement that in RSLogix 500, I'm just stuck on how the "number gets into the PLC in the first place". I'm thinking that it's one of those fun analogue to digital conversion sort of things that I haven't had yet, but I figured I'd check with you guys, to see if I'm right, and whether I'm right or wrong, ask for some pointers to help get me moving in the right direction.

Again, let me re-iterate, I'm not looking for you guys to do my "homework" for me, I'm just looking for a nudge in the right direction. Thank you in advance.

I know, I know, "Cool Story, Bro" so permit me to cut to the chase. The difficulty of the PLC programming challenges I have been given has risen

So here's my dilemma: I need to convert a temperature (In degrees Fahrenheit, and it's a decimal number) to Celsius. I already know the formula I'm going to use, and I have a rough idea how to implement that in RSLogix 500, I'm just stuck on how the "number gets into the PLC in the first place". I'm thinking that it's one of those fun analogue to digital conversion sort of things that I haven't had yet, but I figured I'd check with you guys, to see if I'm right, and whether I'm right or wrong, ask for some pointers to help get me moving in the right direction.

Again, let me re-iterate, I'm not looking for you guys to do my "homework" for me, I'm just looking for a nudge in the right direction. Thank you in advance.