Buzzen

Member

is it necessary to scale a process variable before the pid loop. I will be using a flow meter with a 4-20ma output to control a vfd.

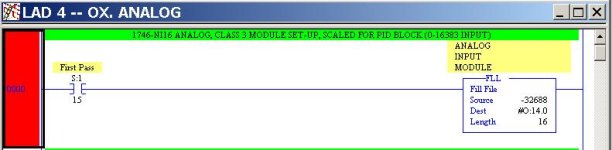

[/"what input module are you using" ? The controller is a 1746-nI16I. The reason I asked about the scaling is because the light for channel status keeps blinking. I went to check the input at a bit level and found that 14 and 15 had a one. Which the book says means over-range detected. I will try the channel config menu you recommended and let u know if it works.

????now does happen manually or auto

PID: Status Indicators

The following status indicators associated with the PID instruction are listed as flags on the right side of the PID Setup screen. Access this screen by clicking Setup Screen on the PID instruction.

AM Auto/Manual Bit (word 0, bit 1) Specifies automatic operation when it is cleared and manual operation when it is set. This bit can be set or cleared by instructions in your ladder program.

Rockwell Software 2000

Will RSLogix add "necessary logic"? Well, I have never been able to get it to add anything. I always have to do it the hard way, adding logic as needed to do the job. Maybe someone knows a short cut.When you do this will it add the necessary logic to the program? Like if I were to choose scale for PID>

The CV from a PID is in the range of 0 to 16383 (represents 0 to 100%). You can change it, in the PID Setup Screen, to be anything from 0 up to 16383. The problem is that an analog output module uses a different range, so the PID output must be scaled.Now does the control variable come off the pid as a percentage or as a 0-16383?