Hi friends, I found there're a lot of skillful peolpe around here such as Mickey and Ron Beaufort. They gave me very good answers for my questions. Here,I want to thank them again.

I have devoloped a lot of different programmes before. I have plenty of programme experience such as C++, assembly language, and PIC18 series. But I am a new member for ML1400. I believe I will become skillful soon with so many friends' help. Here, I have some questions. I hope someone can give me good answers soon.

1. How can I use "continuous scan test" and "test single step" to debug my programme.

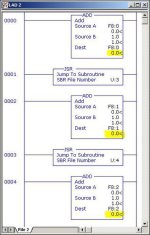

2.Is "SBR" instruction always true? That looks like I don't really need that. What's the nest subroutine meaning? Except using "JSR" instruction to build subroutine, how can I build subroutine efficently? I don't want the subroutine is one of lad files, I want it just is a small section which can be attached anywhere in the lad file. Can you give me some example for how to build a good subroutine?

3.It looks like there is something wrong with one of my programmes:

controller properties rocessor type: BUL.1766 Micrologix 1400 series A

rocessor type: BUL.1766 Micrologix 1400 series A

However,processor status: OS catalog number:1400 series B, proceesor catalog number:1766_LEC

Here, one shows series A, another shows series B, they don't match with each other. But it works well. I have no idea for that.

By the way, what's 1766_LEC meaning here?

4.I don't think I can develop ML1400 programme in a professional way. Can you give me an example with 3 lad files, 4 subrountines, interrupt, and "JMP" instruction? Can you give me some advice how to build programme professionally?

5.I believe an efficient debug way is very important for programme developing and troubleshooting? Can you give me some suggestions about this issue. How to use "TND" efficiently?

6.Do ML1400 have "Watchdog" function?

Thanks.

I have devoloped a lot of different programmes before. I have plenty of programme experience such as C++, assembly language, and PIC18 series. But I am a new member for ML1400. I believe I will become skillful soon with so many friends' help. Here, I have some questions. I hope someone can give me good answers soon.

1. How can I use "continuous scan test" and "test single step" to debug my programme.

2.Is "SBR" instruction always true? That looks like I don't really need that. What's the nest subroutine meaning? Except using "JSR" instruction to build subroutine, how can I build subroutine efficently? I don't want the subroutine is one of lad files, I want it just is a small section which can be attached anywhere in the lad file. Can you give me some example for how to build a good subroutine?

3.It looks like there is something wrong with one of my programmes:

controller properties

However,processor status: OS catalog number:1400 series B, proceesor catalog number:1766_LEC

Here, one shows series A, another shows series B, they don't match with each other. But it works well. I have no idea for that.

By the way, what's 1766_LEC meaning here?

4.I don't think I can develop ML1400 programme in a professional way. Can you give me an example with 3 lad files, 4 subrountines, interrupt, and "JMP" instruction? Can you give me some advice how to build programme professionally?

5.I believe an efficient debug way is very important for programme developing and troubleshooting? Can you give me some suggestions about this issue. How to use "TND" efficiently?

6.Do ML1400 have "Watchdog" function?

Thanks.