ddeshi2

Member

Hi all, This is my first PLC project and I'm trying to implement split range control. I have two valves for Air(LowAir and Large Air)and one flowmeter. Low Air valve is opened first (at low flow rates) and after sometime Large Air valve is opened (keeping the Low air valve opened) as required by the process. The low and high air valves are rated as :

Low Air flow - Min 2.5 SCFM, Max 25 SCFM

Large Air Flow - Min 2.5 SCFM, Max 850 SCFm

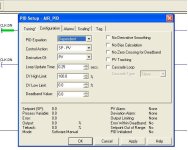

So, when I input a setpoint of 750 SCFM (through HMI) the Low Air valve slowly opens until I reach 25 SCFM (as it is rated max 25 SCFM (4 ma =2.5 scfm and 20ma = 25 SCFM???)) and once it is fully open the Large air valve is controlled to achieve a flow rate of 750 SCFM. I got stuck at scaling the I/O channels and PID parameters.

I'm attaching the program I have written so far (it is not the complete program) .

Also I'm attaching the pdf file of the program written for micrologix so that you can get a clear idea of what I'm talking about.

Thanks in advance!!

Low Air flow - Min 2.5 SCFM, Max 25 SCFM

Large Air Flow - Min 2.5 SCFM, Max 850 SCFm

So, when I input a setpoint of 750 SCFM (through HMI) the Low Air valve slowly opens until I reach 25 SCFM (as it is rated max 25 SCFM (4 ma =2.5 scfm and 20ma = 25 SCFM???)) and once it is fully open the Large air valve is controlled to achieve a flow rate of 750 SCFM. I got stuck at scaling the I/O channels and PID parameters.

I'm attaching the program I have written so far (it is not the complete program) .

Also I'm attaching the pdf file of the program written for micrologix so that you can get a clear idea of what I'm talking about.

Thanks in advance!!