exileaustin

Member

Hello All,

Quick question regarding polling a Modbus device (NuFlo Scanner 2000 flow meter) with a AB CompactLogix and a Prosoft MVI69-MCM card.

I am getting data back from the device, however I am unable to make sense of it.

In the NuFlo user manual it tells me that all the Holding registers are Floating points (At least thats what I think FP means under data type). When I receive the data it is in 2 separate registers and the values are huge

Ex.

MCM.DATA.ReadData[24]= 16288

MCM.DATA.ReadData[25]= -6765

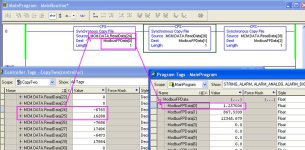

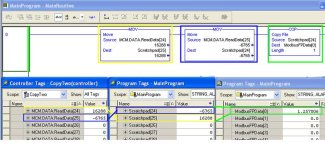

Do these 2 registers have to somehow be combined to get a value from them? If so, which command would I use in RS5000? I have tried using the COP command, and making the destination a real data tag.

Thanks in advance

Austin

Quick question regarding polling a Modbus device (NuFlo Scanner 2000 flow meter) with a AB CompactLogix and a Prosoft MVI69-MCM card.

I am getting data back from the device, however I am unable to make sense of it.

In the NuFlo user manual it tells me that all the Holding registers are Floating points (At least thats what I think FP means under data type). When I receive the data it is in 2 separate registers and the values are huge

Ex.

MCM.DATA.ReadData[24]= 16288

MCM.DATA.ReadData[25]= -6765

Do these 2 registers have to somehow be combined to get a value from them? If so, which command would I use in RS5000? I have tried using the COP command, and making the destination a real data tag.

Thanks in advance

Austin