hello all....

i have a problem with electrical motor ..this may out of the box from plc but i guess all of you in here are genuis..here it goes..

1) 1 of branch plant bought a new pellet mill..which are using direct coupling to the mill..problem was when they start the breaker trip during start up..i had been ask by management to go there and have look ..after checking i feel the electrical motor supply by the supplier are under size but i have too proof them anyway..had check all the mechnical parts even it new installation..now i m confuse..is there any way i could proof them..1 easy way i know to change the breaker too bigger size which are not good at all for long term .

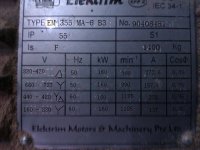

motor spec 160kw amp rated 238.5 volt 440~460

starter board..400amp using auto transformer 65% tapping.

the supplier ask us to change the breaker to bigger size ..but i told them it may solve for short term but long term it not good idea..

could you guys please give me hint how could i proof too them

i have a problem with electrical motor ..this may out of the box from plc but i guess all of you in here are genuis..here it goes..

1) 1 of branch plant bought a new pellet mill..which are using direct coupling to the mill..problem was when they start the breaker trip during start up..i had been ask by management to go there and have look ..after checking i feel the electrical motor supply by the supplier are under size but i have too proof them anyway..had check all the mechnical parts even it new installation..now i m confuse..is there any way i could proof them..1 easy way i know to change the breaker too bigger size which are not good at all for long term .

motor spec 160kw amp rated 238.5 volt 440~460

starter board..400amp using auto transformer 65% tapping.

the supplier ask us to change the breaker to bigger size ..but i told them it may solve for short term but long term it not good idea..

could you guys please give me hint how could i proof too them