We have a conveyor system for boxpallets with a safety zone protected by muted light barriers (Sick M4000 A/P) connected to a Pilz Multi safety controller.

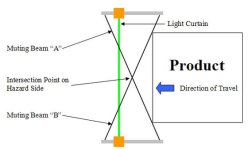

Cross muting is being used.

In a previous slightly different system it worked fine,

but here sometimes the lightcurtain is tripped when a box is moved through the lightbarrier (although not al the time).

The muting sensors are about 25 cm before and after the lightbarrier. The muting sensors use mirrors to send back the signal.

I must say the box is not moved completely in the center between the light barrier sender/receiver and mirror.

What could I do to make the transfer of the boxes more reliable?

Place the muting sensors closer or further from the light barrier? Should I make sure that the center of the transported boxes moves through the crosspoint of the two muting beams or doesn't it matter?

Transfer of boxes is in both directions, should the crosspoint of the muting beams be before, in or after the lightcurtain?.

I already set the simultanity of the muting to a level of 3 seconds, but it didn't help.

Thanks

Cross muting is being used.

In a previous slightly different system it worked fine,

but here sometimes the lightcurtain is tripped when a box is moved through the lightbarrier (although not al the time).

The muting sensors are about 25 cm before and after the lightbarrier. The muting sensors use mirrors to send back the signal.

I must say the box is not moved completely in the center between the light barrier sender/receiver and mirror.

What could I do to make the transfer of the boxes more reliable?

Place the muting sensors closer or further from the light barrier? Should I make sure that the center of the transported boxes moves through the crosspoint of the two muting beams or doesn't it matter?

Transfer of boxes is in both directions, should the crosspoint of the muting beams be before, in or after the lightcurtain?.

I already set the simultanity of the muting to a level of 3 seconds, but it didn't help.

Thanks