dcooper33

Lifetime Supporting Member + Moderator

Hi all,

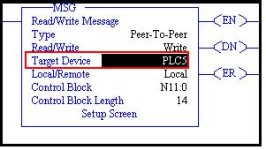

I'm venturing into new territory, programming MSG instructions for the first time

What I'm wanting to do is send an alarm bit from a SLC to a PLC-5 over DH+ to trigger an alarm in the 5, and then when the alarm is acknowledged by a push button on the machine with the PLC-5, send an acknowledge request back to the SLC.

After reading the help files, and instruction set manuals for both processor types, I think I understand how to set the parameters, but I've still got a really dumb question: On a MSG write from 500 to 5, do you have to have a corresponding MSG read instruction on the target device (5), and vice versa?

Also, I'm wondering if it would be better to only trigger the MSG instructions when an alarm condition exists, or rather just cycle the transfers continuously. I only want to transfer one word at a time(say N7:0), which from the 500 to 5 would be a 1 when in alarm and 0 when clear, and on the 5 to the 500 the word (call it N7:1) would be a 1 when the alarm acknowledge request was set, and then reset to 0 upon completion of MSG transfer.

I played with it some today at work, but didn't have much luck. After more studying, I see several things I was doing wrong, but I'm still unclear about whether the instructions have to be paired on the target device.

Any help/advice would be much appreciated.

Thanks,

Dustin

I'm venturing into new territory, programming MSG instructions for the first time

What I'm wanting to do is send an alarm bit from a SLC to a PLC-5 over DH+ to trigger an alarm in the 5, and then when the alarm is acknowledged by a push button on the machine with the PLC-5, send an acknowledge request back to the SLC.

After reading the help files, and instruction set manuals for both processor types, I think I understand how to set the parameters, but I've still got a really dumb question: On a MSG write from 500 to 5, do you have to have a corresponding MSG read instruction on the target device (5), and vice versa?

Also, I'm wondering if it would be better to only trigger the MSG instructions when an alarm condition exists, or rather just cycle the transfers continuously. I only want to transfer one word at a time(say N7:0), which from the 500 to 5 would be a 1 when in alarm and 0 when clear, and on the 5 to the 500 the word (call it N7:1) would be a 1 when the alarm acknowledge request was set, and then reset to 0 upon completion of MSG transfer.

I played with it some today at work, but didn't have much luck. After more studying, I see several things I was doing wrong, but I'm still unclear about whether the instructions have to be paired on the target device.

Any help/advice would be much appreciated.

Thanks,

Dustin