escoplcguy

Member

Hey guys!

Think this is a straight forward question...

is it possible for me to get 100 readings per second logged from 10 defferent tags using FT Historian.....

PLC = not chosen yet......thinking compactlogix or SLC 5/05

just want to know if it is possible and if so what are some things i need to look at when getting this much data logged...

ALSO...

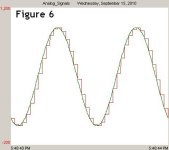

When setting up a trend, can the plots x and y be user set of only one and the other is default to time

Think this is a straight forward question...

is it possible for me to get 100 readings per second logged from 10 defferent tags using FT Historian.....

PLC = not chosen yet......thinking compactlogix or SLC 5/05

just want to know if it is possible and if so what are some things i need to look at when getting this much data logged...

ALSO...

When setting up a trend, can the plots x and y be user set of only one and the other is default to time