iraiam

Member

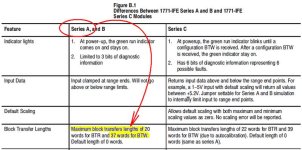

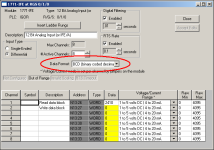

I set up an analog card (1771-IFE/A) in differential mode, this gave me 8 functional analog inputs. I used the RSLogix generated rungs with a BTW word length of 37 and a BTR word length of 20.

At work I see numerous analog modules with BTR & BTW that have a completely different word length, only a couple of these analog inputs are used on the module, the rest are shorted to module common.

I have been unable to understand the relationship between word length and the number of active inputs on the module as of yet, (if there is one)

Here is a simple ladder to help, all 8 differential inputs work, I only scaled one so far.

Any understanding you can give me would be much appreciated

At work I see numerous analog modules with BTR & BTW that have a completely different word length, only a couple of these analog inputs are used on the module, the rest are shorted to module common.

I have been unable to understand the relationship between word length and the number of active inputs on the module as of yet, (if there is one)

Here is a simple ladder to help, all 8 differential inputs work, I only scaled one so far.

Any understanding you can give me would be much appreciated