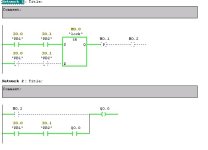

Hello, I am in school learning about PLC and RLL and my professor gave us an assignment to try to figure out how to write code for a anti tie down non repeat circuit using just 2 push buttons and 1 output light but we cannot use timers just b3 internal relays.

I have sat for hours writing different codes and cant seem to figure out how he does it. I have read every thread on here about these circuits so I know people are gonna say its been discussed many many times. Sorry for the repeat... I just haven't seen too much info doing it this method.

any help would be greatly appreciated.

I have sat for hours writing different codes and cant seem to figure out how he does it. I have read every thread on here about these circuits so I know people are gonna say its been discussed many many times. Sorry for the repeat... I just haven't seen too much info doing it this method.

any help would be greatly appreciated.