Hello,

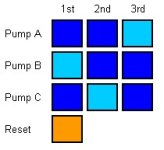

I am looking for some advice. This is RS Logix 5000 and Panelview Plus with Factory Talk ME 5.1. There are three motors A, B, and C, which have to start in sequence for example A - first, B - second, and C - third. This order has to be selected by operator. So on HMI screen under each motor start/stop control I have placed three multistate pushbuttons. These multistate pushbutton will write value 1, 2, or 3 to the tag of respective motor. This tag will define, where in sequence start of each motor will take place. Operator will assign start order for each motor, 1, 2, or 3. So far so good. What I am struggling with how to make impossible to assign the same number to two or three motors.

Any suggestion?

I am looking for some advice. This is RS Logix 5000 and Panelview Plus with Factory Talk ME 5.1. There are three motors A, B, and C, which have to start in sequence for example A - first, B - second, and C - third. This order has to be selected by operator. So on HMI screen under each motor start/stop control I have placed three multistate pushbuttons. These multistate pushbutton will write value 1, 2, or 3 to the tag of respective motor. This tag will define, where in sequence start of each motor will take place. Operator will assign start order for each motor, 1, 2, or 3. So far so good. What I am struggling with how to make impossible to assign the same number to two or three motors.

Any suggestion?