jeddog

Member

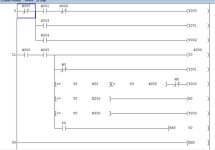

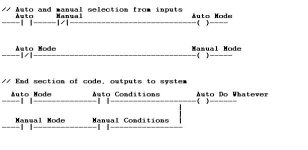

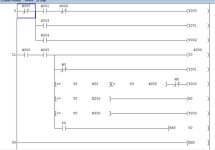

I am writing this ladder for a competence test. The outputs seem to over ride each other and not work.

eg when on manual, the auto stops the outputs from working and visa versa

Can someone please have a look and let me know where Im going wrong?

regards James

PS. Written with Mitsubishi GX Developer

eg when on manual, the auto stops the outputs from working and visa versa

Can someone please have a look and let me know where Im going wrong?

regards James

PS. Written with Mitsubishi GX Developer