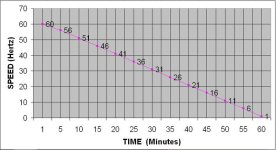

i have a hydraulic pump which is attached to a pusher this hydraulic pump work with the help of .75 kw three phase ac motor .now i want a control system such that if i enter the time as maximum as the pusher will completed in the given time means if i will enter 60 then the pusher will complete push displacement in 60 minute if 1 then it will push in 1 minute

now i can connect the drive to the hydraulic pump and by using the drive potentiometer i can control the motor speed and increase or decrease the displacement time of pusher ..but instead of that potentiometer which show me rpm i want a display and a input device in which if i enter the time the rpm will set according to time

if any dive or interface is available in market so please tell me i am using power flex 4m

now i can connect the drive to the hydraulic pump and by using the drive potentiometer i can control the motor speed and increase or decrease the displacement time of pusher ..but instead of that potentiometer which show me rpm i want a display and a input device in which if i enter the time the rpm will set according to time

if any dive or interface is available in market so please tell me i am using power flex 4m