hi ...

i am trying to make another excersices with ( batch process ) simultion in Logixpro .

my idea concept is without using ( counter + timers ) to design a program to meet the folloeing requiremts :

1- fill the batch tank with pump 1 only . ( no mixturing here )

2- when the tank was full pump 3 must be open to drain the tank .

3- pump 1 and pump 3 are not working together .

4- when we start the simulation by using start bottun system must fill and drain contiuously , and stop just when we push the stop bottun .

( counter + timers + flowmeter + thermostate + mixer )can not be used.

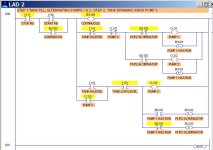

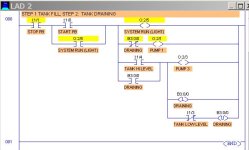

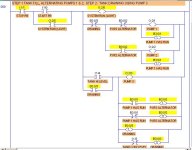

that is my try , but im having difficulty to make it work continuously .

i am trying to make another excersices with ( batch process ) simultion in Logixpro .

my idea concept is without using ( counter + timers ) to design a program to meet the folloeing requiremts :

1- fill the batch tank with pump 1 only . ( no mixturing here )

2- when the tank was full pump 3 must be open to drain the tank .

3- pump 1 and pump 3 are not working together .

4- when we start the simulation by using start bottun system must fill and drain contiuously , and stop just when we push the stop bottun .

( counter + timers + flowmeter + thermostate + mixer )can not be used.

that is my try , but im having difficulty to make it work continuously .