Hi all and happy holidays!

I'm self-teaching PLC wiring/programming and I'm currently working on controlling a 450W electric heater. I eventually want to hook it up to a SLC-500 with an analog card, temp sensor and PanelView C600 and be able to set Manual and Auto mode, with temp setpoint, etc, but for now, I'm just playing with the wiring on my ML1000 (cheaper if I mess it up, hehe)

The problem is that I only have a limited selection of relays and have selected the following for my experiment:

1 DPDT, 24VDC, with allowable contact power of 1540VA, 300W, 10A relay

3 SPDT, 24VCD, with allowable contact power of 1540VA, 300W, 10A relays

It appears that I will only be able to power on the heater for a few seconds, just for testing purposes until I can get relays with a higher-rated load.

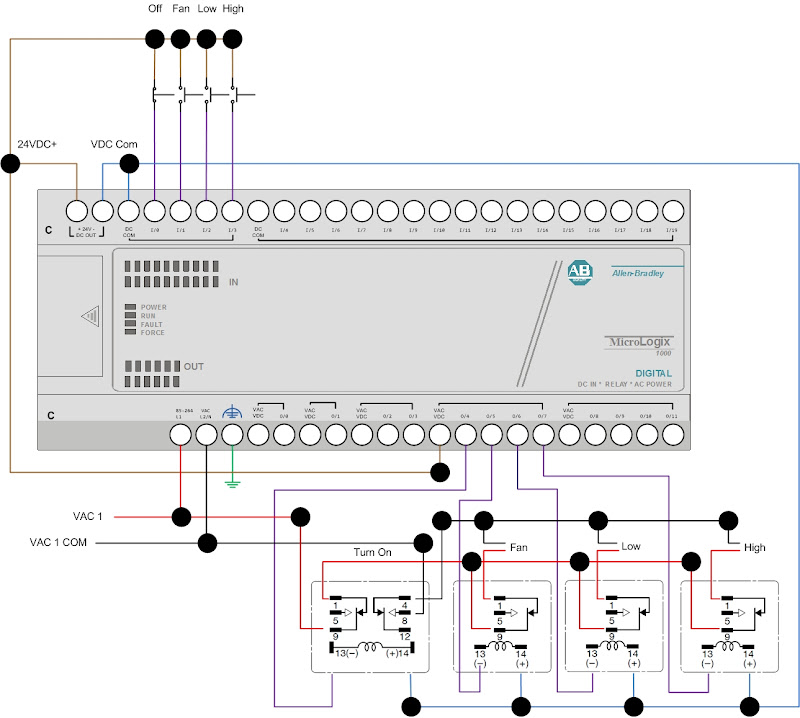

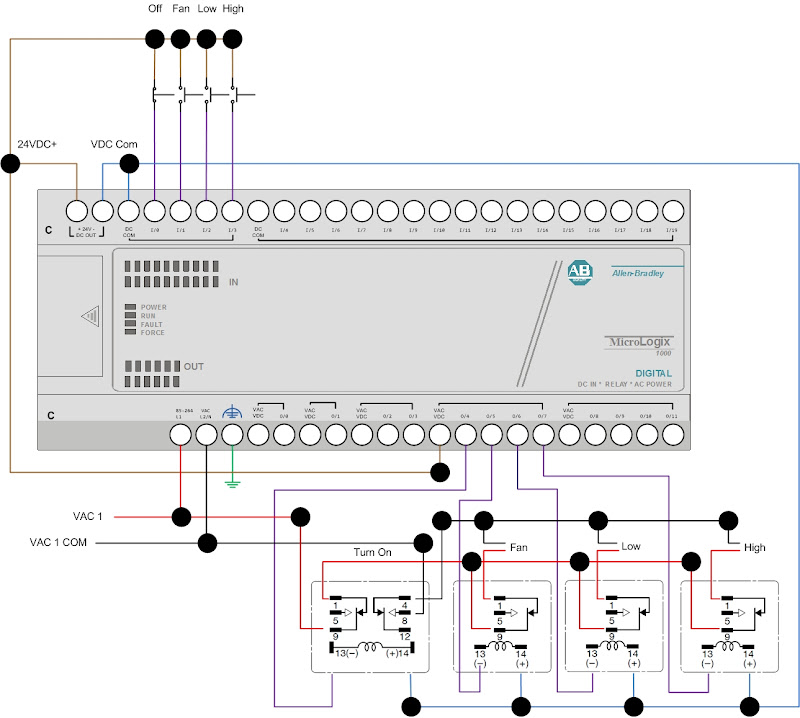

I'm obviously not going to run the AC loads through the internal PLC coils, I'm only going to use the built-in 24VCD power supply to activate (close) the relay contacts. I want to run the AC loads through the relay contacts as shown in the following diagram:

I'm new at making electrical wiring installations (my background is in c++ development), but find this field extremely interesting and rewarding. I'm also learning electrical circuits, etc as time permits.

My question/concern is: Am I correct in assuming that the way I'm wiring the AC loads, isolate the PLC coils completely and there's no risk of damaging it?

Thanks in advance!!!

I'm self-teaching PLC wiring/programming and I'm currently working on controlling a 450W electric heater. I eventually want to hook it up to a SLC-500 with an analog card, temp sensor and PanelView C600 and be able to set Manual and Auto mode, with temp setpoint, etc, but for now, I'm just playing with the wiring on my ML1000 (cheaper if I mess it up, hehe)

The problem is that I only have a limited selection of relays and have selected the following for my experiment:

1 DPDT, 24VDC, with allowable contact power of 1540VA, 300W, 10A relay

3 SPDT, 24VCD, with allowable contact power of 1540VA, 300W, 10A relays

It appears that I will only be able to power on the heater for a few seconds, just for testing purposes until I can get relays with a higher-rated load.

I'm obviously not going to run the AC loads through the internal PLC coils, I'm only going to use the built-in 24VCD power supply to activate (close) the relay contacts. I want to run the AC loads through the relay contacts as shown in the following diagram:

I'm new at making electrical wiring installations (my background is in c++ development), but find this field extremely interesting and rewarding. I'm also learning electrical circuits, etc as time permits.

My question/concern is: Am I correct in assuming that the way I'm wiring the AC loads, isolate the PLC coils completely and there's no risk of damaging it?

Thanks in advance!!!

Last edited: