The letters to the left of the rungs convey MUCH MORE meaning than just whether you are inserting, editing, or deleting rungs.

But firstly, let's make one thing absolutely clear.

THERE IS NO "EDITING" TAKING PLACE IN THE PLC !

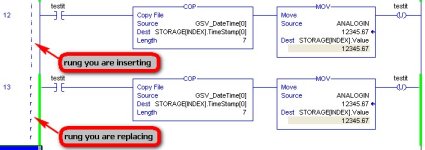

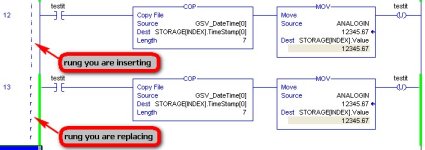

When you start a rung edit

online, you will be given a fresh copy of the rung you are editing, marked with an "i". This is notation for the rung you are

inserting. The original rung is marked with an "r". This is notation for the rung will be

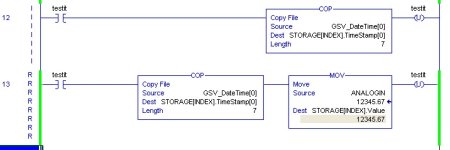

replaced by the "i" rung. See first picture (It doesn't matter that the pic shows ControlLogix - all A-B editing works the same way).

The "i" and "r" markers are in

lower case, which means they still in your PC, not in the PLC. If you went offline and walked away, you would not have done anything at all to the PLC !!

Now make changes to your rung (you can only change the "i" rung), and until it is verified, it changes to an "e" marker, indicating this rung is being edited or entered. It has to be verified (it goes back to an "i" marker), before you can put your edits into the PLC.

To do that, you have to "Accept" edits, that is actually when the verified rung is put into the PLC.

What happens next depends on whether the PLC is in RUN mode or PROGRAM mode.

If PROGRAM mode, the new "i" rung goes in and replaces the "r" rung, and everything is done. "d" rungs just get deleted.

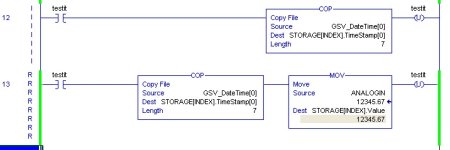

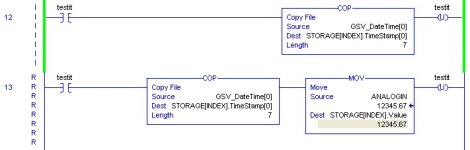

If RUN mode, the new "i" rung goes into the PLC just above the "r" rung it is replacing, BUT, the "i" and "r" markers change to

UPPER-CASE "I" and "R". Capital letters indicate program changes that are in the PLC. See second picture.....

If you went offline now, and walked away, you have still not made the program changes you need to, because the PLC is still executing the old "R" rung(s). Notice how the power-bars are still green for "R" rungs, and black for "I" rungs.

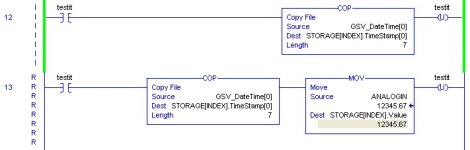

What you have to do now, is TEST EDITS. This will switchover the rungs, so that your new "I" rung(s) become active, and the old "R" rungs are not executed. See third picture....

This gives you the opportunity to review your handiwork, and ensure that the edit does the job. If it doesn't, you can UNTEST EDITS, which puts it back as it was, and you can either have another stab at editing the "I" rung, or CANCEL EDITS and give up!

In TEST EDITS mode, when you are satisfied the new rung(s) work(s) as intended, you ASSEMBLE EDITS, to complete the job.

In summary....

i = a verified rung you are inserting, but not yet in the PLC

e = an unverified rung in the PC, you cannot accept this to send it to the PLC until verified

r = a rung you will be replacing by the i rung

d = a rung you have marked for deletion, not yet in the PLC

I = a rung you are inserting - this is in the PLC

R = a rung you are replacing - this is in the PLC

D = a rung you are deleting - this is in the PLC

Power-Bar is Green = rung is being scanned.

Power-Bar is Black = rung is not being scanned.

Accept Edits = Send the edited rung(s) to the PLC

Test Edits = Switch to test the edited rungs

Untest Edits = Restore the original rungs

Cancel Edits = Give Up (can only cancel from Untest Edits mode)

Assemble Edits = Finish the job (can only assemble from Test Edits mode