robw53

Member

i am after some advice just to get me on the most suitable path, for the best (slickest) way to achieve this....

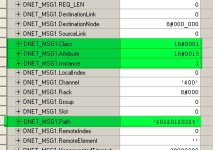

i am wanting to be able to store all the parameters for the drives in the PLC and if a drive goes down, swap it out and then download that settings to the drive, but also the ability to call them from the drive to display them and edit and redownload the ones that had been changed.

i have created a UDT with all the parameters, i just want alittle advice on which is the best route to go down with regards the messaging style, i am wanting to put all this into an AOI to duplicate on multiple machines.

anyway here is what i am thinking so far...

i was thinking of either using one message instruction and changing the path to whichever ethernet address i am after, and then having seperate message instructions for each parameter and sending them sequencially using the DN bit from the previous message to set the next message.

or a message instruction for each drive and then one instruction per drive for the read parameter and one per drive for the right parameter and sequence through them until all of them have been transfered.

Rob

i am wanting to be able to store all the parameters for the drives in the PLC and if a drive goes down, swap it out and then download that settings to the drive, but also the ability to call them from the drive to display them and edit and redownload the ones that had been changed.

i have created a UDT with all the parameters, i just want alittle advice on which is the best route to go down with regards the messaging style, i am wanting to put all this into an AOI to duplicate on multiple machines.

anyway here is what i am thinking so far...

i was thinking of either using one message instruction and changing the path to whichever ethernet address i am after, and then having seperate message instructions for each parameter and sending them sequencially using the DN bit from the previous message to set the next message.

or a message instruction for each drive and then one instruction per drive for the read parameter and one per drive for the right parameter and sequence through them until all of them have been transfered.

Rob