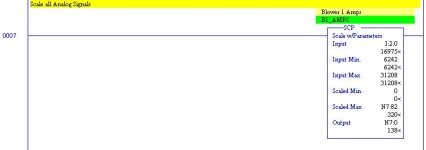

I am trying to scale a value to read in Eng.units. I am applying 4 - 20mA into an analog card with the counts being 3277 - 16384. I ruined my brain trying to figure out the SCL function with no luck and couldn't figure out the tag scaling on the PanelView550 either so I thought I'd do it in the logic and just display the integer value on the display. I don't usually do the programming around here so I'm a little rusty on the scaling math. In short I want to take my 4 to 20 mA and display it as 0 to 100 PSI. If anyone can give me a clue I'll be forever grateful. God bless you.

Brian

Brian