Ron Beaufort

Lifetime Supporting Member

I had a new member call me earlier - and since I don't do Omron, I suggested that he post his question here ... he is in the process of joining the forum - but there might be a (security) delay in how soon he is allowed to post ...

I offered to post the question for him - hopefully the forum will be able to give him some guidance ...

I offered to post the question for him - hopefully the forum will be able to give him some guidance ...

Ron,

Here is my question. Thanks for posting it for me.

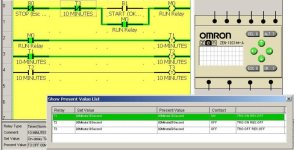

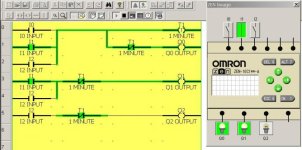

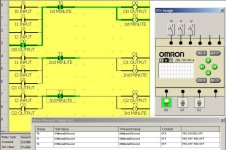

I have an Omron Zen with 4 outputs (Q0-Q3)

I am trying to set it up to control three outputs with timers. Each Input does a different timer, but some share outputs and the software keeps giving me an error with duplicate outputs. An example of what I am trying to do is below.

Input I0: Output Q0 for one minute.

Input I1: Output Q0, Q1 for one minute.

Input I2: Output Q0,Q1 and Q2 for one minute.

I understand how ladder logic and if/then works, but I don't know how to make the software do this. I can make it work as long as there are no shared outputs. I am completely new to PLC programming but I can do this if I can get past the problem I am having now. Is there any way to share outputs?

I have spoken to someone at Omron who got me started, but he told me to "play with it a while then call if I got stuck". I called him back and he told me how it could be done but didn't want to help me any further. I need someone to SHOW me how to do it.

Thanks in advance for any help!

--

Shawn